We Have The Best Flooring Glue Built to Hold Tight

At Rustic Wood Floor Supply, we’ve spent years helping pros and homeowners build solid, long-lasting floors. Our hardwood flooring adhesives are trusted for their strong bond, quick setup, and consistent performance on real job sites. From engineered planks to solid hardwood, we stock high-performance adhesives that are easy to work with and built to last. These aren’t off-the-shelf glues, but they’re trusted by flooring crews who can’t afford delays or do-overs.

Strong Hold. Smooth Results.

That’s how we help you stick to high standards.

Trusted By

Top American Flooring Brands

At Rustic Wood Floor Supply, we know the importance of dependable products that get the job done right. That’s why leading flooring contractors and manufacturers across the country rely on us for their adhesives and sundry supplies. Our products meet rigorous industry standards and deliver consistent, long-lasting results you can count on. When you partner with us, you’re working with a supplier trusted by pros who expect nothing but the best.

Join the ranks of top professionals nationwide

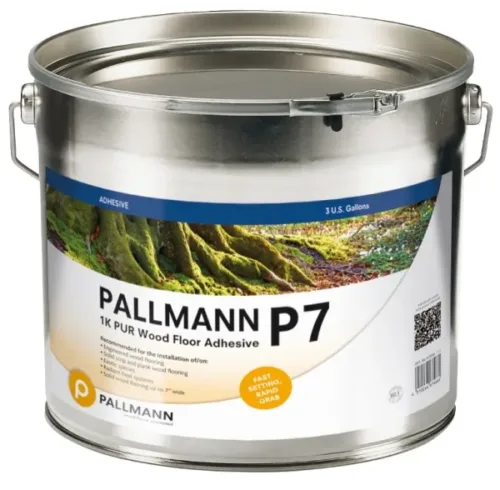

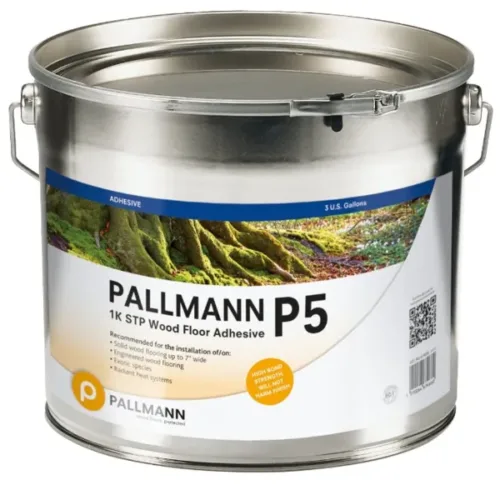

Silane & Polymer Glues

Struggling with floorboards that lift or crack because your glue can’t keep up? That’s a common headache in hardwood installation. Our silane and polymer-based adhesives are designed to hold tight without losing flexibility, letting your floors breathe with seasonal changes. Contractors trust these glues for their easy cleanup and long-lasting performance.

Why Modified Silane Adhesives Lead The Way

Rustic Wood Floor Supply offers modified silane based adhesive that combine strength and flexibility like no other. Trusted by experts across the U.S., these adhesives resist UV damage, bond to multiple surfaces without primers, and keep your project safe with no harmful isocyanates. They deliver reliable performance so your floors stand up to the test.

Key Benefits of Modified Silane Adhesives:

- Flexible Strength: Stretch up to 100% to 300% without breaking.

- Strong Hold: Tensile strength ranges from 1 to 4 MPa, with some epoxy versions hitting 8 MPa.

- UV Resistant: Stands up to sunlight exposure without breaking down.

- Paint Friendly: Can be painted quickly, even while still wet, saving you time.

- Multi-Surface Bonding: Works on metal, ceramic, plastic, and more.

- Health Conscious: Free of isocyanates, lowering health risks on the job.

Get the grip your floor deserves with Rustic Wood Floor Supply.

How are these Flooring Adhesives and Glues

Industry’s Top Choices?

At Rustic Wood Floor Supply, our best flooring glues are built tough to handle whatever Mother Nature throws at them, hot summers, freezing

winters, and everything in between. They’re easy to use, dry fast, and create a rock-solid hold that stands the test of time. When you pick our

adhesives, you’re getting professional results.

FEWER CALLBACKS. BETTER INSTALLS. GET YOUR GLUE HERE.

TESTIMONIAL

Stick With The Best in The Business

When your flooring job demands precision, performance, and lasting results, Rustic Wood Floor Supply delivers. We stock high-performance adhesive for wooden flooring that stands up to seasonal shifts, heavy use, and demanding job sites. Contractors nationwide rely on our products to keep floors secure, smooth, and stunning project after project.

You don’t just get the job done, but you get it done right with our expert support and handpicked supplies.

Gear Up With Confidence. Explore More Professional-Grade Adhesives Here!

Frequently Asked Questions

No, just because it is easier to spread does not mean it is less sticky. The beauty of a Silane based glue for flooring is that is moves with the wood and is extremely sticky without ruining the wood flooring if it touches it.

Yes, the Silane glues we sell work for all the products that we sell.

Different glues allow for different widths. It is recommended to check the label and buy accordingly. Each of our glues has the width rating listed on their respective pages. Some of the glues allow unlimited width.

It is recommended to clean the glue droppings/mess up within 45 min as it is not skinned over yeat and has yet to bond to anything. The easiest way to do this is with a damp cloth.

Silane glue is a very popular hardwood flooring glue that is considered “new” generation of glues. These glues offer no need to mix, dry fast and have awesome elasticity. Typically these glues have a skin time of 4-60 min and a full cure time of 18-24 hours. We recommend Silane glues from pallmann and loba as they work well in our climate to allow movement without sheering the glue to board bond.