Premium Sandpaper Atlanta

Stock up on wholesale floor sandpaper from flooring store Atlanta for smooth, professional results. Durable grits and rolls built to handle heavy sanding and fine finishing alike.

Hardwood Floor Sandpaper Atlanta

Tired of burning through sheets before the job’s halfway done? Cheap abrasives waste time and leave uneven results. Our professional-grade sandpaper delivers consistent performance, room after room. Trusted by Atlanta flooring pros for its durability, sharpness, and clean finish from the first pass to the final polish.

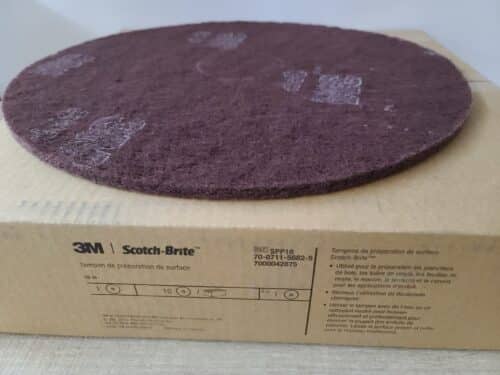

Brands trusted on job sites across the country:

- 3M

- Norton

- Festool

Sandpaper Belt Atlanta

Old finishes shouldn’t slow you down or leave your work looking patchy. Our sanding belts power through tough layers without leaving scars behind. They grip your sander tightly, move smoothly, and let you focus on progress, not fixing mistakes.

Most-used belt options include:

- Norton Red Heat 8″ Belt: 8″ x 29-1/2″

- Norton Red Heat 8″ Belt Sandpaper: 10″ x 29-1/2″

- Norton Orange Blaze 8″ Belt: 10″ x 29-1/2″

- 3M Regalite 12″ Belt: 12″ x 31-1/2″

- 3M Regalite Belt: 8″ x 29-1/2″

- 3M Regalite Belt: 10″ x 29-1/2″

- 3M Regalite 8×19″ Belt: 8″ x 19″

Floor Sandpaper Rolls Atlanta

When rolls tear mid-project or dull halfway through, it puts your whole job at risk. We supply pro-grade sanding rolls made to work with drum sanders at a commercial pace. They wrap tightly, stay centered, and deliver even results across large surfaces.

Top picks for long sanding days:

- 12″ Red Heat Roll

- 12″ Orange Blaze Roll

Sanding Discs Atlanta

Low-quality sanding discs slow progress and fill the air with dust. We stock sanding discs that are built to grip, cut clean, and hold their edge. No more wasting time switching out weak discs. Each one is designed for a specific machine and stage.

High-performance sanding discs are available:

- 5″ Red Heat Disc

- 5-7/8″ Red Heat Disc

- 6″ Red Heat Disc

- 7″-5/16″ Red Heat Disc

- 8″ Red Heat Disc

- 5″ Mesh Disc

- 6″ Mesh

- 7″ Mesh Disc

- 8″ Mesh

- 5″ Clean Sanding Discs

- 5″ 8 Hole Regalite Disc

- 5″ Gold Hookit-II Disc

- 6″ 6-Hole Regalite Disc

- 6″-7/8″ Hole Disc

- 7″ No Hole Quick Change Regalite Disc

- 7-5/16″ Reaglite Disc

Floor Sanding Pads Atlanta

Loose or misaligned buffer pads make sanding frustrating and unsafe. Our wood floor sanding pads Atlanta lock onto machines fast and stay in place until the job is complete. They’re made for tough scrubbing, delicate finishing, and everything between.

Popular buffer pad choices:

- Maroon/SPP Pads

- Thin White Driver Pads

- Easy Change Systems

- Sanding Screens

- Red Scrubbing Pads

- Thick Polish Pads

Intercoat Abrasion Sandpapers Atlanta

A smooth finish begins with strong bonds between coats. Our abrasion sandpapers create the grip each new layer needs to stay in place. They gently scratch the cured finish to help the next coat adhere without fail, removing surface contamination in the process.

Precision options that make every coat count:

- PSA Roll

Built for Results. Designed Around Your Work.

Every floor tells a story, and yours should speak of craftsmanship, not shortcuts. Our hardwood

floor sandpaper delivers the excellence needed.

TESTIMONIAL

Trusted by Americans for Real Flooring Experience

Rustic Wood Floor Supply is proud to stock sanding tools that deliver real value. Every option we carry is tested, proven, and preferred by installers who do this every day. We’re not just suppliers. We’ve been on floors ourselves, so we only offer what we trust in our own work.

Buy tools that work hard and deliver results you can stand on.

Frequently Asked Questions

Norton blaze is for ripping finish off and getting hte floro flat. Red heat is good for refinishes that are pretty flat already and for final sanding. THAT DOES NOT MEAN red heat cannot be used for intial cuts, orange blaze just lasts longer and is sharper. However, the blaze mineral is not the best for final sanding on a belt. The scratches are deeper.

Each manufacturer of sandpaper has different levels of sandpaper. The highest current grain is full ceramic. The full ceramic lasts longer, does NOT create bad scratches and is decent pricing. Overall you will find that 3M will last long and works well, but does not excel at any given thing. Norton paper is made in different types and the different types work great fo different senarios and produce less scratches.