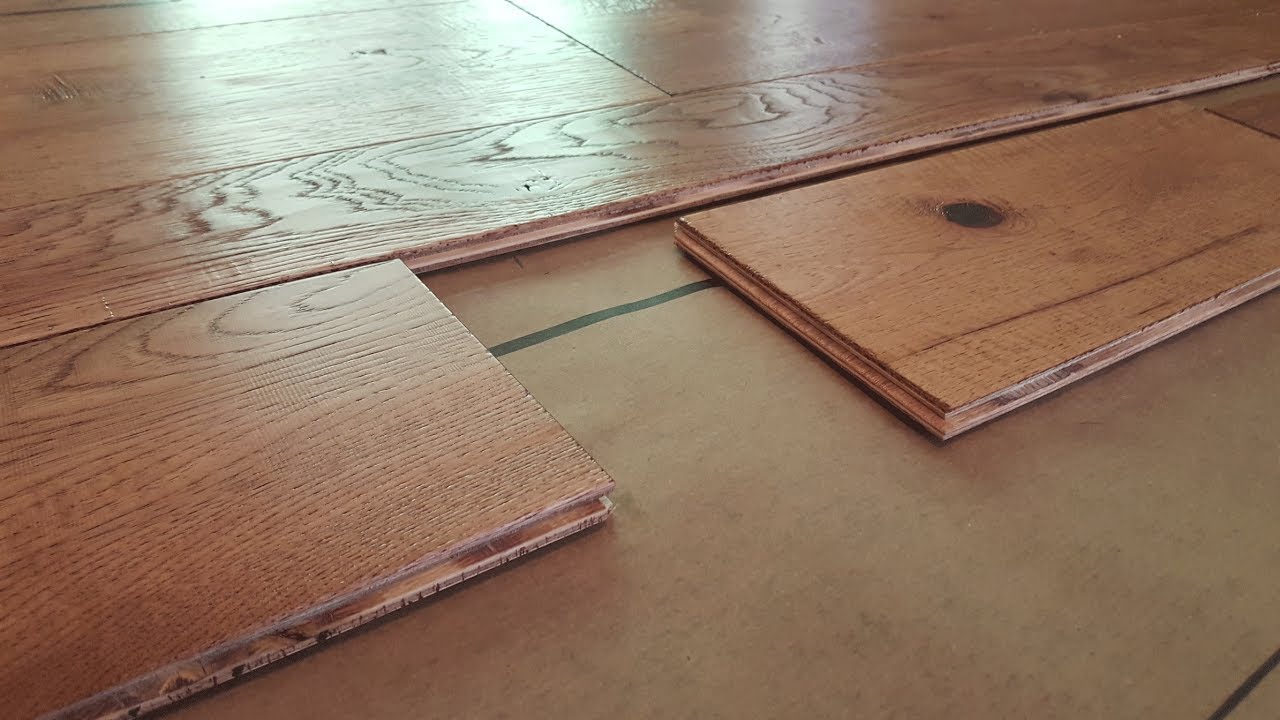

As a hardwood flooring contractor, your craft involves transforming spaces with the timeless beauty of hardwood flooring either by sanding existing flooring or installing new flooring. To ensure your projects meet the highest standards, the proper care and maintenance of your machinery is crucial. We will explore essential machine maintenance tips that can help you achieve precision and excellence in your hardwood flooring projects. All flooring machines need maintenance including belt sanders, drum sanders, edgers, orbitals, vacuums and dust extractors, nailers, and saws.

Regular Cleaning Routine:

Just as a pristine hardwood floor requires regular cleaning, so do the machines. Sawdust and debris can accumulate over time, affecting the performance and accuracy of your equipment. Develop a consistent cleaning routine by removing dust, dirt, and any other residues from your machines after each use. Many contractors choose to blow out the machines to easily remove dust. This process can allow you to better identify areas that are worn and need repair.

Lubrication is Key:

Proper lubrication is essential for the smooth operation of your machines. Be sure to follow the manufacturer’s recommendations for lubricating various parts of your equipment. Regularly check and replace oil or grease to prevent wear and tear, ensuring your machines function optimally. Rustic Wood Floor Supply Atlanta knows the importance of keeping nailers properly oiled, non-lubricated nailers are prone to breaking regardless of what type of fasteners are being used.

Blade Maintenance:

The quality of your hardwood flooring is directly impacted by the condition of your saw blades. Keep blades sharp by sharpening or replacing them as needed if important. Dull blades not only compromise the precision of your cuts but also put unnecessary strain on your machinery. Dull blades can cause the flooring to splinter along the cuts.

Alignment Checks:

Misaligned machinery can result in uneven and subpar floor sanding. Regularly check and adjust the alignment of your equipment to ensure accuracy in cutting and sanding hardwood. Proper alignment not only improves the quality of your work but also extends the lifespan of your machines. Many contractors check their sandpaper to see if the machine is sanding evenly. Wheels are another big cause of alignment issues, check edger and big machine wheels to ensure the bearings are good and the wheel is not nicked or damaged. Lagler Hummels often need fresh bearings to ensure the wheels spin freely.

Electrical System Inspection:

The machinery’s electrical components are critical to its overall functionality. Periodically inspect the wiring, switches, and electrical connections to identify and address any issues promptly. Ensure that all safety features, such as emergency shut-off switches, are properly working to protect both the machine and the operator. Brushes and fuses are some of the most commonly replaced parts in American Sanders floor sanders and should be checked and changed regularly to ensure the machines are working well. Brushes and capacitors are not always easy to change yourself and come with some risk because you are working in electrical systems, Rustic Wood Floor Supply Atlanta can change brushes and replace capacitors quickly and get your machines running again.

Dust Collection Systems:

Hardwood flooring projects generate a considerable amount of dust. A dust collection system not only keeps your workspace clean but also plays a vital role in maintaining the longevity of your machinery. Clean or replace filters and bags regularly and ensure that the system is functioning at its optimal capacity.

Operator Training and Awareness:

Equip your team with the knowledge and skills needed to operate and maintain the machinery properly. Regular training sessions can help prevent accidents, reduce wear and tear caused by operator error, and ensure that everyone is on the same page regarding maintenance protocols. Training your team on maintenance can help them identify when to stop using a machine to ensure more damage is not created by running the sanders.

In the world of solid unfinished hardwood flooring, precision is paramount. By implementing a proactive machine maintenance routine, you not only enhance the longevity and performance of your equipment but also elevate the quality of your craftsmanship. Consistent care and attention to detail will set you apart as a hardwood flooring contractor committed to excellence.

If you don’t have the time to maintain your flooring machines yourself the team at Rustic Wood Floor Supply in Boise, Atlanta & Spokane is here to help. Rustic offers full-service machine repair services including parts and labor. We diagnose the machine’s error, source the parts needed for the repair, and make the needed repairs.

Author Profile

- I have worked in hardwood flooring for the last 8 years. Use to run a company of residential crews as well as a company with gym flooring. If you need floor installation or refinishing help, I should have an answer or at least get you in the right direction.

Latest entries

FlooringJuly 18, 2025The Rise of Luxury Vinyl Plank Floors: What Buyers Should Know

FlooringJuly 18, 2025The Rise of Luxury Vinyl Plank Floors: What Buyers Should Know FlooringJuly 18, 2025Why Oil-Based Finishes Are Returning for High-End Wood Floors?

FlooringJuly 18, 2025Why Oil-Based Finishes Are Returning for High-End Wood Floors? Hardwood FlooringJune 21, 2025How to Find FSC-Certified Wholesale Wood Flooring: Your Complete Guide

Hardwood FlooringJune 21, 2025How to Find FSC-Certified Wholesale Wood Flooring: Your Complete Guide Hardwood FlooringJune 18, 2025Wholesale vs. Retail Wood Flooring: What’s the Difference in Quality?

Hardwood FlooringJune 18, 2025Wholesale vs. Retail Wood Flooring: What’s the Difference in Quality?