When you visit different stores, you’re bound to encounter a barrage of information about the products they sell. These products are often presented as “amazing” and the ultimate solution for all your needs, convincing you that you won’t require anything else for the rest of your life. However, we’re all aware that these marketing techniques aim to entice you into purchasing products that will likely need replacement in a few years. At Rustic Wood Floor Supply in Boise and Spokane, we frequently receive a common question: Is engineered hardwood better than solid hardwood? This question is brought up almost every week, with customers visiting the store based on recommendations from their installers, who usually advocate for engineered hardwood. In this article, we will delve deep into this topic and discover that seeking advice from professionals who have experience installing both types of flooring is crucial, rather than solely relying on the store’s perspective.

Understanding Each Option – Engineered vs Solid

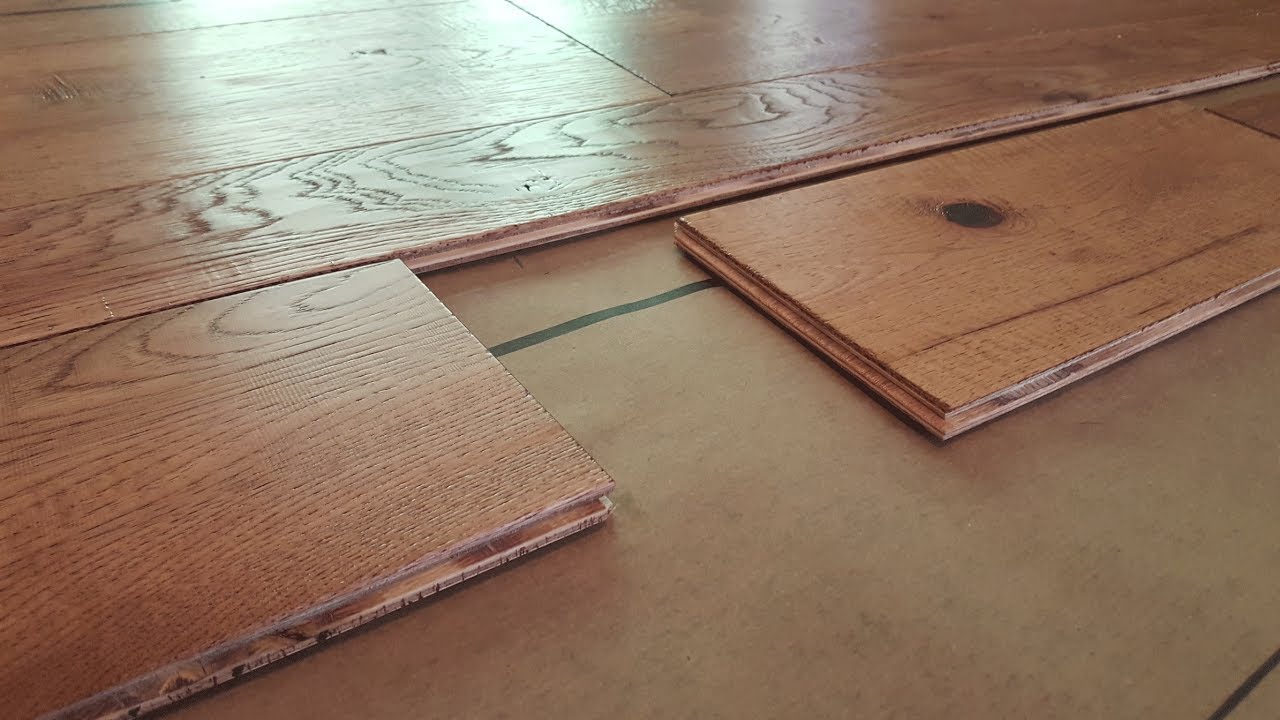

Engineered hardwood is a type of flooring that consists of multiple layers of wood, commonly referred to as the “core.” These layers typically comprise softwoods like birch or pine, which are bonded together to form the majority of the flooring structure. On top of this core, there is a veneer layer that varies in thickness from 1mm to 6mm. Thinner cores are associated with thinner veneer layers, while thicker cores result in thicker veneer layers. This correlation between the core and veneer thickness is crucial for ensuring the stability of the product. If the core is too thin but the veneer is thicker, the flooring may experience issues such as warping and checking. Additionally, engineered hardwood flooring is finished with a UV-cured finish in most cases, although it can also be treated with an “oil” finish.

On the other hand, solid hardwood is a straightforward flooring option that consists of solid pieces of hardwood cut to size, featuring a tongue and groove for installation. There is no adhesive or additional manufacturing involved. The process is simple: the hardwood is harvested from the forest, transported to the mill, cut into appropriate sizes, and then shipped to the store. The wear layer of solid hardwood typically ranges from 7mm to 6mm, depending on the profile of the cut. Unlike engineered hardwood, solid hardwood is not finished at the mill and is instead delivered to the store with the raw wood face, without any applied finish.

Examining the Details

Now that we have a clear understanding of each option and how they are manufactured, it is important to discuss the topic of which flooring is superior. While this may make some readers uncomfortable if they strongly favor one side or the other, it is crucial to consider the facts rather than focusing solely on factors like price or dust accumulation. We are solely interested in determining whether engineered hardwood flooring is truly better, stronger, and more durable than solid hardwood flooring.

Warranty Considerations

Engineered Hardwood Flooring: Typically, engineered hardwood floors are the only type of flooring that comes with a warranty. This is because they are entirely man-made, involving the use of chemicals, adhesives, and machinery in the manufacturing process. The warranty exists due to the common issues associated with engineered products, such as adhesive failure, excessive movement of the core affecting the veneer, and veneer cracking due to issues with the core. Even higher-end engineered products, such as those offered by Urban Floors, are not exempt from occasional issues since humans and machines are not flawless.

Solid Hardwood: Solid hardwood flooring, on the other hand, does not require a warranty beyond the cutting and milling process. Any warranty-related concerns would typically fall under the responsibility of the contractor if they fail to install the flooring according to industry standards.

Finish and Wear Layer – What You Really Want to Know

When stores claim that engineered hardwood is “stronger, more durable, and overall better,” it can be somewhat amusing. Simply because a box boasts a “50-year warranty” means very little. If you carefully read the warranty details, you will come across interesting clauses. One significant clause is that at least 20% of the floor must have worn through to qualify for a warranty related to wear. In normal circumstances, you don’t walk on 20% of your floor. Typically, you walk on 5-10% of the floor repeatedly, following specific patterns. Just like cars, trucks, dirt bikes, UTVs, houses, yards, and toys, maintenance is the key to ensuring the longevity of a high-quality, long-lasting product. The most reliable cars on the market, such as Toyota (known for their longevity), require regular maintenance to keep them running smoothly. While a lack of maintenance may allow them to outlast other brands, without proper care, they will prematurely deteriorate.

Engineered flooring features a strong top coat, which primarily protects against wear and tear caused by abrasion. However, the top coating does not prevent denting or scratching, as some people tend to believe. The key to a long-lasting floor lies in its foundational structure. In the case of engineered hardwood flooring, the core and veneer are its essential components. A soft core will not support a strong veneer, and similarly, a soft veneer but a hard core will not provide any benefits. Both the core and veneer need to be strong and hard. Most engineered floors on the market consist of a white oak veneer with a pine or birch core. Birch, being one of the softest hardwoods, and white oak, which possesses decent strength, contribute to the likelihood of denting, much like solid hardwood.

When it comes to solid hardwood, the primary concern is the Janka rating of the wood. Hardwoods like white oak, maple, and hickory have the ability to withstand significant wear over time. Hickory, being the hardest domestic wood, is nearly impervious to damage when accompanied by a suitable top coating such as Arboritec, Loba, or Glitsa. The strength of the coating in terms of wear resistance is on par with that of engineered flooring.

My thoughts

With my experience as a hardwood flooring company owner for over seven years, specializing in both residential and commercial projects, including notable installations like the Boise Recreational gym center, I can confidently attest to the superiority of solid hardwood flooring. Solid hardwood simply outlasts any other attempts to imitate its authenticity and durability. It offers the advantage of being fixable and easily replaceable with matching boards if the need arises, making it a highly practical and long-lasting choice. I have personally worked on numerous homes with solid hardwood floors that have surpassed the century mark in age, as well as gyms with floors that have endured for 75 years. In contrast, imitation wood products are frequently torn out and replaced due to their inherent limitations. One major drawback of engineered flooring is its limited ability to be sanded, typically allowing for only 0 to 2 sanding cycles. Consequently, it becomes challenging to refinish an engineered floor purchased from a store. In my opinion, solid hardwood offers a wide range of options in terms of colors, sheens, and overall aesthetics, providing unparalleled versatility. On the other hand, engineered flooring restricts you to a single option, which often becomes difficult to source just twelve months down the line. In most cases, opting for a decent engineered floor doesn’t result in significant cost savings when compared to a solid hardwood flooring solution. In fact, cheap engineered floors tend to be riddled with warranty issues and are generally unreliable.