At our warehouse and showroom (Boise & Spokane), we regularly discuss with our customers and their clients the various options available for hardwood flooring. We’ve noticed that many people come to our store without having the correct information about the products they’re interested in, and many stores that only sell a limited range of options may not have a full understanding of each product they offer. Through these conversations, we’ve gained a firm understanding of what other people might tell you or what you might learn that is simply false, semi-untrue, or just straight-up selling nonsense.

At our warehouse and showroom (Boise & Spokane), we regularly discuss with our customers and their clients the various options available for hardwood flooring. We’ve noticed that many people come to our store without having the correct information about the products they’re interested in, and many stores that only sell a limited range of options may not have a full understanding of each product they offer. Through these conversations, we’ve gained a firm understanding of what other people might tell you or what you might learn that is simply false, semi-untrue, or just straight-up selling nonsense.

We hope that this guide will help you make an informed decision when choosing between solid unfinished hardwood flooring, solid prefinished flooring, and engineered hardwood flooring.

Flooring terms you need to know for hardwood flooring:

- Sandable: Refers to the ability of flooring to be sanded at a later time to remove dents and scratches or to change the color and sheen.

- Wear layer: The thickness of the hardwood veneer on top of engineered hardwood flooring. A wear layer over 4mm is sandable if smooth, while anything under that depends on the texture of the flooring.

- Square edge: A flooring edge that has no visible seam or bevel, resulting in a seamless look once installed.

- Beveled edge: Refers to the slight angle on the flooring’s edges. This is required because the floor is not sanded and variations in the subfloor can create height differences. The bevel allows your foot to move smoothly over the flooring without getting caught on any unevenness.

- Glue assist: Refers to putting down an “s” pattern or strips of glue to prevent the wood from moving or lifting at the back. This is necessary for flooring over 5″ in width and for lower-thickness woods where nails do not set correctly.

- Full spread: Applying glue to 100% of the flooring area during installation.

Let’s start by going over the different Flooring options available:

- Solid Unfinished Wood Flooring – This is the oldest form of hardwood flooring available and is made from solid hardwood that is cut from a tree. The planks have a tongue and groove and a square edge, which means there are no cracks or seams like other wood flooring types. The wood is dried in kilns to 6-9% moisture, making it the most environmentally friendly option as it requires fewer steps to create. This type of wood flooring can be sanded 4-5 times and can last for decades if not centuries. If you ever get tired of the look of this flooring, you can wirebrush it, stain it, or change the sheen to give it a fresh look without having to replace the entire floor.

- Solid Prefinished Wood Flooring – This is a solid piece of wood that has been stained and prefinished in a factory in the USA or Canada. It resembles unfinished solid wood, but it doesn’t require sanding. You may notice that the planks have bevels, which differentiate each plank. This type of wood flooring is less environmentally friendly than solid wood as it comes in boxes and requires additional steps to create. However, it can be sanded 3-4 times, just like solid unfinished wood, and is a long-lasting floor that can be modified in the future via stains.

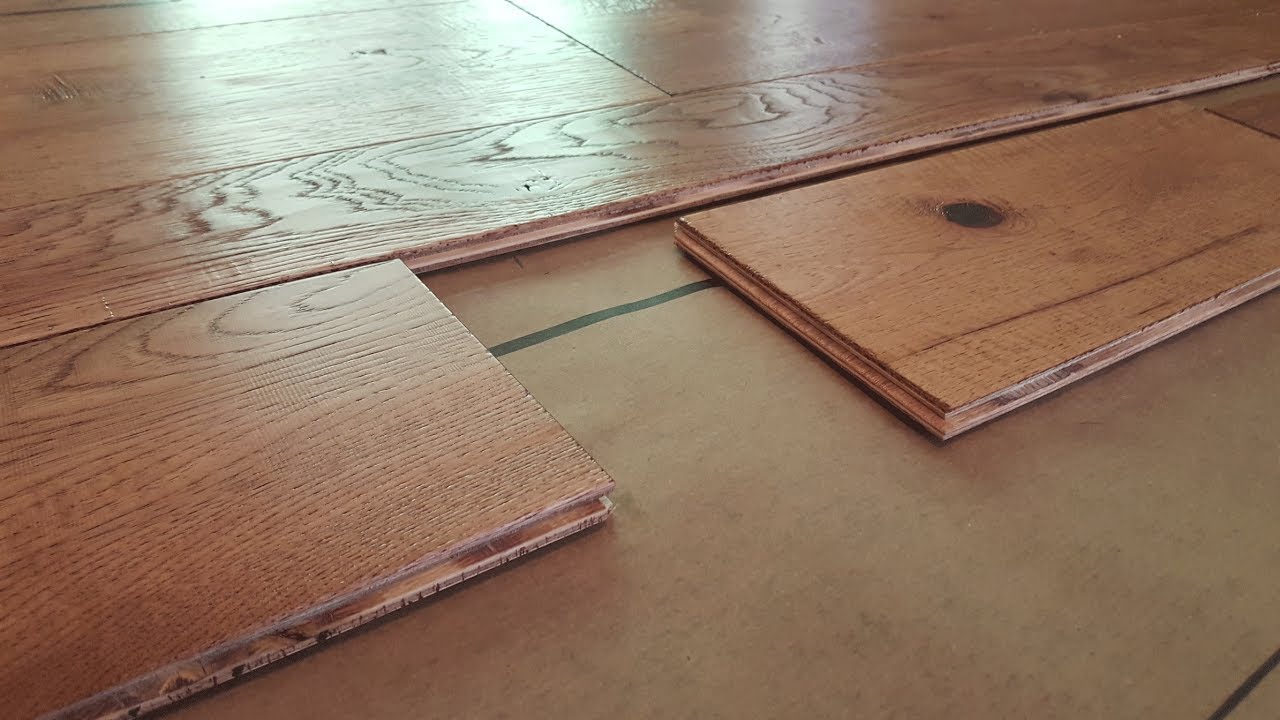

- Engineered Hardwood Flooring – This type of flooring is typically found in strip mall flooring stores and is usually produced overseas. Engineered hardwood is made up of multiple layers of plywood and a veneer on top. The layers of plywood are glued and pressed together, and the floor is generally unsandable as the wear layer has too big of a bevel, a small wear layer, and has been wirebrushed too deeply. This option is made from US wood that is sent to China for production and then sent back to the US, resulting in a high carbon footprint. If you need to change this floor, you’ll have to rip it out and start over, which can be problematic if you need to glue the subfloor.

This is the baseline knowledge of the flooring options you have in the market today.

The Pro’s Of Each Flooring Option

Solid Unfinished Flooring

Prefinished products may become discontinued if they do not sell well, but solid hardwood flooring will never be discontinued because the raw material – the wood – is grown on trees and can always be harvested. This means that if you have a hickory floor installed today, you can always add onto it or match it in 30 years’ time.

Solid hardwood flooring that is site-finished typically has square edges without any bevels. Beveled edges can collect dust and dirt, leaving remnants in the cracks, whereas solid flooring is easier to clean and maintain since it has no inherent cracks.

Solid flooring is essentially the same as other types of flooring, except that it is finished on site. However, solid unfinished hardwood flooring offers the same variety of options that you would find in any store in the Boise or Spokane area. It can be stained in any color, wire-brushed or hand-scraped, and finished with any level of gloss.

Solid unfinished flooring is actually the most environmentally friendly flooring option available today, despite what the marketing industry may lead you to believe.

Prefinished Solid Flooring

Prefinished solid hardwood flooring offers a wide range of color and sample options, allowing you to see the finished product on a larger scale before starting the project. This provides a reliable way to visualize the final look of your floor and make an informed decision about the color and style that best suits your needs and preferences.

Prefinished solid hardwood flooring is ready to be installed right after an acclimation period. The wood is stained, textured, and finished at the factory, so there is no need to go through the process of staining, texturing, or finishing it on-site after securing it with staples or cleat fasteners.

Engineered Hardwood Flooring

Engineered hardwood flooring is often available in wider planks than solid or prefinished hardwood flooring, as it is made by peeling wood and then layering it together. This method allows for wider planks to be produced in larger quantities compared to solid or prefinished hardwood flooring. Typically, engineered hardwood planks range from 5 to 10 inches in width, but wider options may also be available depending on the manufacturer.

Engineered hardwood flooring offers an extensive palette of colors to choose from, providing a vast array of options for those seeking a very specific color or style. With the availability of such a broad range of colors, you can rest assured that your specific color needs can be met and that the product is ready to be installed.

The Con’s Of Each Flooring Option

Solid Unfinished Flooring

It is not possible to install an unfinished hardwood floor today, as it requires a finishing process that typically takes about a week to complete. In comparison, prefinished solid hardwood flooring can be installed more quickly, typically taking around three days. Therefore, choosing prefinished solid hardwood can speed up the installation timeline compared to unfinished hardwood flooring.

Cracks are an inevitable aspect of any wood-based flooring, regardless of the type. Engineered hardwood flooring may have fewer cracks than other types, but it can still move over time. The reason why cracks are less noticeable in engineered flooring is due to the presence of bevels. On the other hand, solid unfinished hardwood flooring may show more cracks, even if it is the same as engineered flooring. In some cases, the way the wood is cut can affect the amount of cracking due to moisture. While this can be a disadvantage, it is not a cause for concern if you take proper care of the humidity and temperature levels in your home. All types of flooring can move if they are not properly maintained.

Prefinished Solid Flooring

While it is generally easy to match the color of solid prefinished hardwood flooring with stains, the presence of bevels can create an issue for matching later on. Colors can go in and out of style, and become difficult to find years later, making it challenging to match the color of beveled flooring during an add-on project. On the other hand, solid prefinished flooring is less likely to go out of production, making it easier to find and match if an add-on project is needed in the future. However, it’s always a good idea to keep extra planks from the original installation to ensure a seamless match if an add-on is required.

Compared to other types of flooring, solid prefinished hardwood flooring does use more resources, energy, and packaging to manufacture. While it may not be as detrimental to the environment as some types of engineered hardwood flooring, there is still an impact to consider. However, it’s worth noting that solid prefinished hardwood flooring is a long-lasting and durable flooring option, which can make it a more environmentally friendly choice over time, as it will not need to be replaced as frequently as other types of flooring. Additionally, choosing sustainably sourced wood and eco-friendly finishes can further reduce the environmental impact of this type of flooring.

The bevels in engineered hardwood flooring can limit the number of times the flooring can be sanded, which can be considered a disadvantage compared to solid prefinished hardwood flooring. Generally, you may lose one or two sandings on engineered hardwood flooring due to the presence of bevels, compared to solid prefinished flooring. Therefore, if you anticipate needing to refinish your floors several times over their lifespan, solid prefinished hardwood flooring may be a better option for you.

Engineered Hardwood Flooring

While it is true that engineered flooring can have issues with delamination or the veneer layer coming off, this is generally not a common occurrence with high-quality engineered products from reputable manufacturers. Additionally, the adhesive used in the production of engineered flooring is designed to withstand the stresses of everyday use and is typically very durable. Solid flooring, on the other hand, can also experience issues such as cupping, warping, or cracking due to changes in humidity and temperature. Both types of flooring have their own potential problems, and it is important to choose a high-quality product from a reputable manufacturer and to properly maintain and care for your floors to avoid issues. Even with a reputable company – you will have issues from time to time.

It is true that the colors of engineered hardwood flooring may not last as long as those of solid hardwood flooring. They can fade or change within 2-3 years, and the color can also vary between different production runs, making it challenging to match during an add-on project. To ensure a consistent look, it is recommended to purchase extra flooring during the initial installation or to purchase all the necessary flooring for an add-on project at the same time. This can help to avoid frustration and ensure a seamless match.

Potential Problems of Each Flooring Type

Unfinished Hardwood Flooring

While unfinished solid hardwood flooring has its benefits, such as the ability to customize the stain and finish, it also comes with some challenges. The most common issues include cracking and movement of the flooring.

Preventing Movement

The biggest challenge of unfinished solid hardwood flooring is preventing the wood from moving, which can cause gaps or warping. One way to prevent this is to keep the heat and humidity in your home consistent throughout the year. This can be achieved by using a humidifier or dehumidifier as needed and making sure your HVAC system is properly maintained.

Another way to prevent movement is to choose the correct width for each wood type.

- Red oak and white oak flooring should be below 5 inches in width

- Hickory should be less than 5 inches

- Maple should be 4 inches or below

- Additionally, a good moisture barrier between the subfloor and the hardwood can help prevent movement. We recommend a roll-on moisture barrier by Pallmann or Wakol.

Overcoming the Challenges

While it may seem daunting to ensure your house has the correct humidity and heat levels, it is a relatively simple task that can be easily managed. By following the recommended wood widths for each type and using a good moisture barrier, you can minimize the risk of cracking and movement in your solid hardwood flooring. It’s worth noting that these challenges apply to prefinished solid and engineered hardwood flooring as well.

Prefinished Hardwood Flooring

Solid prefinished hardwood flooring is a popular choice for homeowners who want the beauty and durability of hardwood floors without the hassle of finishing them on-site. However, there are some challenges that come with this type of flooring.

Climate Control

One of the biggest challenges of solid prefinished hardwood flooring is that, like solid unfinished hardwood, it is sensitive to changes in humidity and temperature. If your home’s climate is too dry, the wood can shrink and cause gaps between the boards. If it’s too humid, the wood can expand and cause cupping or buckling. To prevent these issues, it’s important to keep your home’s climate within a certain range and to use a humidifier or dehumidifier as needed.

Header: Matching Wood

Another challenge of solid prefinished hardwood flooring is that it can be difficult to match the wood stain color if you need to replace or add to your flooring later on. While some manufacturers may offer the same product for several years, there is always a risk that the color or grain pattern will be slightly different. This is especially true if you have a custom stain or finish on your floors. If you need to replace or add to your flooring in the future, you may need to resand and restain the entire floor to get a consistent look.

Engineered Hardwood Flooring

As your trusted supplier of engineered hardwood flooring, we want to be transparent about some of the challenges that come with this product. We understand that our customers value consistency, quality, and sustainability, and we want to address some of the biggest concerns that you may have.

Matching Color Lots

One issue that we often hear about is matching color lots. We know how frustrating it can be to order flooring one month and then receive a completely different color the next month. Unfortunately, this is a common problem with engineered hardwood flooring, as the wood can have variations in color and tone. To avoid this issue, we highly recommend that you order extra flooring to ensure you have enough of the same lot number for your project.

Manufacturing Issues

Another issue that can arise with engineered hardwood flooring is manufacturing issues. Because this product is made in a factory, there can be issues with the glue or plywood that affect the quality and durability of the flooring. Our team takes every precaution to ensure that our products are made and applied correctly, but we cannot guarantee that every piece will be perfect.

Earth Friendly is not a Thing

Finally, we know that many of our customers are concerned about the environmental impact of their flooring choices. While engineered hardwood flooring may use less wood than solid hardwood, it is not necessarily a more sustainable option. In fact, the manufacturing process often involves the use of chemicals, plastics, and packaging that can have a negative impact on the environment. Additionally, once the flooring has been installed, it cannot be resanded or refinished, making it a one-time-use product.

Experience and Variety at Rustic Wood Floor Supply

At Rustic Wood Floor Supply, we pride ourselves on having hundreds of years of combined experience in the industry, selling a wide range of flooring products to meet all of our customers’ needs. We don’t just sell one type of flooring, like solid wood or prefinished wood or LVP. We offer all the options, so you can find the perfect flooring for your situation.

Quality and Value

We believe in offering high-quality, contractor-grade products that are meant to last and provide our customers with the best value. Our products are used by flooring installers who trust and recommend Rustic Wood Floor Supply to their clients.

Visit Our Showroom

We encourage our customers to come in and see our showroom, ask questions, and check out our samples. Seeing the flooring in person can help you make an informed decision about which product is the best fit for your home. We are committed to providing our customers with the best possible service and expertise to ensure that they are happy with their flooring choice.

Whether you are a homeowner, contractor, or designer, Rustic Wood Floor Supply is your one-stop-shop for all your flooring needs. Come visit us today to see the best flooring available for your house!