Engineered hardwood flooring has gained immense popularity in recent years due to its versatility, durability, and aesthetic appeal. However, many homeowners and prospective buyers may wonder whether engineered hardwood floors are sealed and how different finishes affect their performance and maintenance. In this article, we will explore the various aspects of engineered hardwood floor sealing, including the types of engineered hardwood, the difference between sealer and finish, the types of sealers used, waterproofing capabilities, the number of finish layers, and how wood and finish interact when it comes to scratches and dents.

Types of Engineered Hardwood Floors:

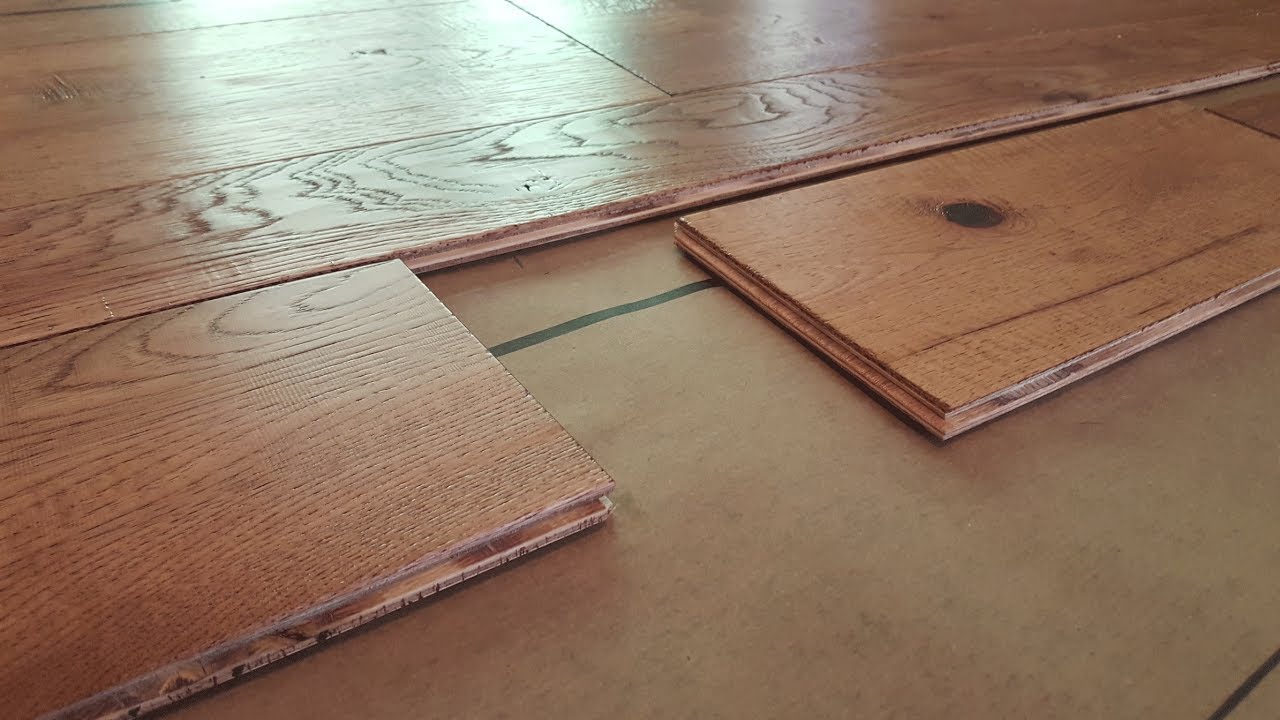

Before delving into the engineered hardwood flooring sealing aspect, it’s essential to understand that there are two primary types of engineered hardwood floors: unfinished and finished. These two types may share a core composed of multiple layers, but they differ significantly in their surface treatment.

- Unfinished Engineered Hardwood: In unfinished engineered hardwood flooring, the veneer (the topmost layer of real wood) of engineered hardwood flooring is not coated with a finish. Instead, it is directly applied to a plywood core layer. Typically, the veneer on unfinished engineered hardwood is relatively thick, ranging from 3 to 6 millimeters.

- Finished Engineered Hardwood: Conversely, finished engineered hardwood features a veneer that is pre-coated with a protective finish. This veneer is also laid on a core of plywood, which is usually thinner, ranging from 1 to 5 millimeters in thickness.

Difference Between Sealer and Finish in Engineered Hardwood Flooring:

In the world of engineered hardwood floors, the terms “sealer” and “finish” are often used interchangeably. Both sealer and finish serve to protect the wood and enhance its appearance. The primary distinction is that a sealer is the initial protective layer applied to the wood, while the finish is the subsequent coating(s) that further seal and beautify the surface.

Different Types of Sealers Used on Engineered Hardwood:

There are several types of sealers used on engineered hardwood flooring, each with its unique properties and maintenance requirements:

- Urethane: Urethane sealer is a water-based, UV-cured finish that is relatively easy to clean and maintain. However, it typically requires a maintenance coat every 5 to 7 years to keep it looking pristine. Although the finish may have a warranty for up to 25 years, it will gradually degrade over time.

- Penetrating Oil: Penetrating oil is a product that is applied and UV-cured but does not create a film on top of the wood. Instead, it penetrates the wood and becomes an integral part of it. This option tends to be more maintenance-intensive, requiring care every 1 to 3 years.

- Oil-Based Finish: This is a rare option, similar to urethane but made with oil. Over time, an oil-based finish may develop a yellowish hue.

Waterproofing of Sealed Engineered Hardwood Floors:

It’s crucial to understand that no floor, including engineered hardwood, is entirely waterproof. Even so-called waterproof floors can eventually allow water to seep through to the subfloor. While sealed engineered hardwood can repel water for a certain period, it is not impervious to water damage. Regardless of the sealer or finish used, wood remains permeable and will react to environmental conditions.

Number of Layers of Finish or Sealer on Engineered Hardwood Flooring:

Engineered hardwood floors typically have 5 to 7 layers of finish or sealeer, with each layer being UV-baked to ensure durability. This multi-layer approach contributes to the floor’s strength, surpassing that of solid hardwood flooring.

Scratch Resistance of Wood and Finish:

When it comes to scratches and dents, it’s essential to consider that the type of wood used in engineered hardwood plays a significant role in the floor’s performance. The finish itself is generally strong and not prone to scratching. However, different wood species have varying hardness levels, affecting their susceptibility to dents.

In practice, it’s often the wood that dents, while the finish remains relatively unscathed. Harder wood species may give the impression of a more “robust” finish because they are less prone to dents. Opting for a lower-sheen finish can also be advantageous, as it tends to hide scratches (commonly referred to as dents) more effectively from the naked eye.

In conclusion, engineered hardwood floors are indeed sealed, with various types of sealers and finishes available to enhance their performance and appearance. While these finishes provide protection against scratches and stains, they are not entirely waterproof, and the choice of wood species can impact the floor’s resilience. Proper maintenance, including periodic resealing or refinishing, is essential to ensure the longevity and beauty of engineered hardwood floors.