Engineered Hardwood Flooring

Moisture ruining your floors? We’ve got a smarter solution!

At Rustic Wood Floor Supply, our engineered hardwood flooring is made for your homes, especially in moisture-prone areas like basements. Moisture is a basement’s biggest challenge, but engineered hardwood is built to handle it. Unlike solid wood, it stays strong and steady, even when damp. Its layered construction adds durability, keeping your floors looking great for years. DIY enthusiasts appreciate how easy it is to install, while contractors rely on its durability and stability to deliver professional results.

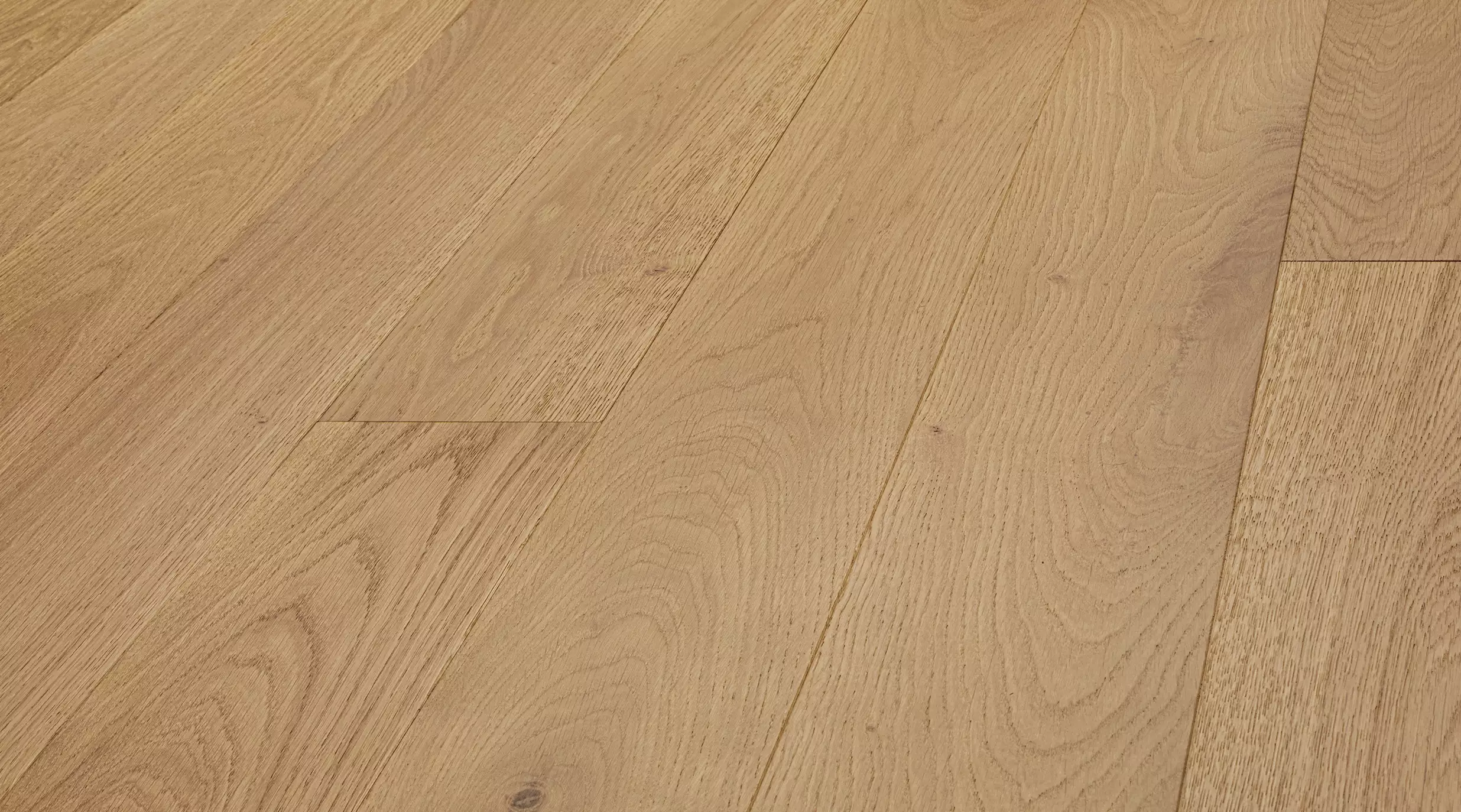

Cordalera Lakes Colletion – Engineered Hardwood

5/8″ Thick | 4mm Veneer | UV Finish

Why Our Engineered Hardwood is Best Choice?

Our best engineered hardwood flooring is sourced from trusted mills that meet the highest standards. Each plank is built to handle tough humidity and temperature swings, so your floors stay beautiful and strong for years.

Our Engineered Hardwood Looks Good Forever

We know great flooring needs to do more than just look nice. It should handle busy foot traffic, stand up to wear, and bring character to any space. That’s why we carry collections designed for real-life use in homes, shops, offices, and everything in between.

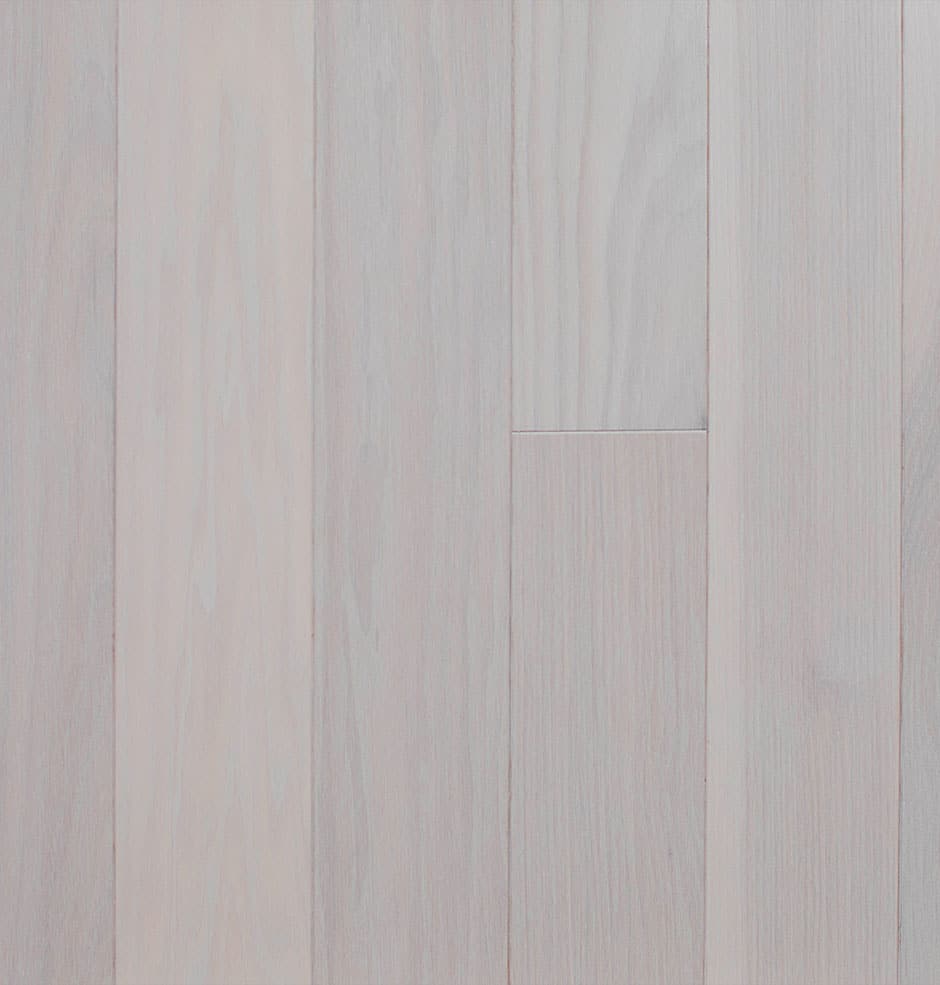

Cordalera Lakes Collection

Clean lines, modern feel, and built for durability. Cordalera Lakes is a smart choice for high-traffic areas like retail stores or busy households. Its UV finish helps resist scuffs and wear.

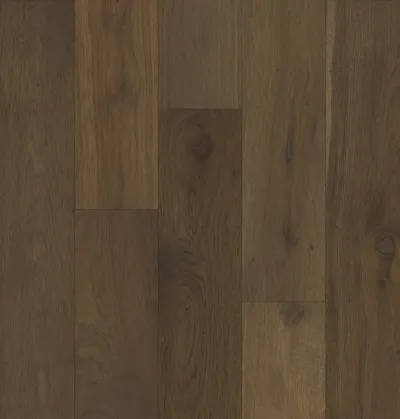

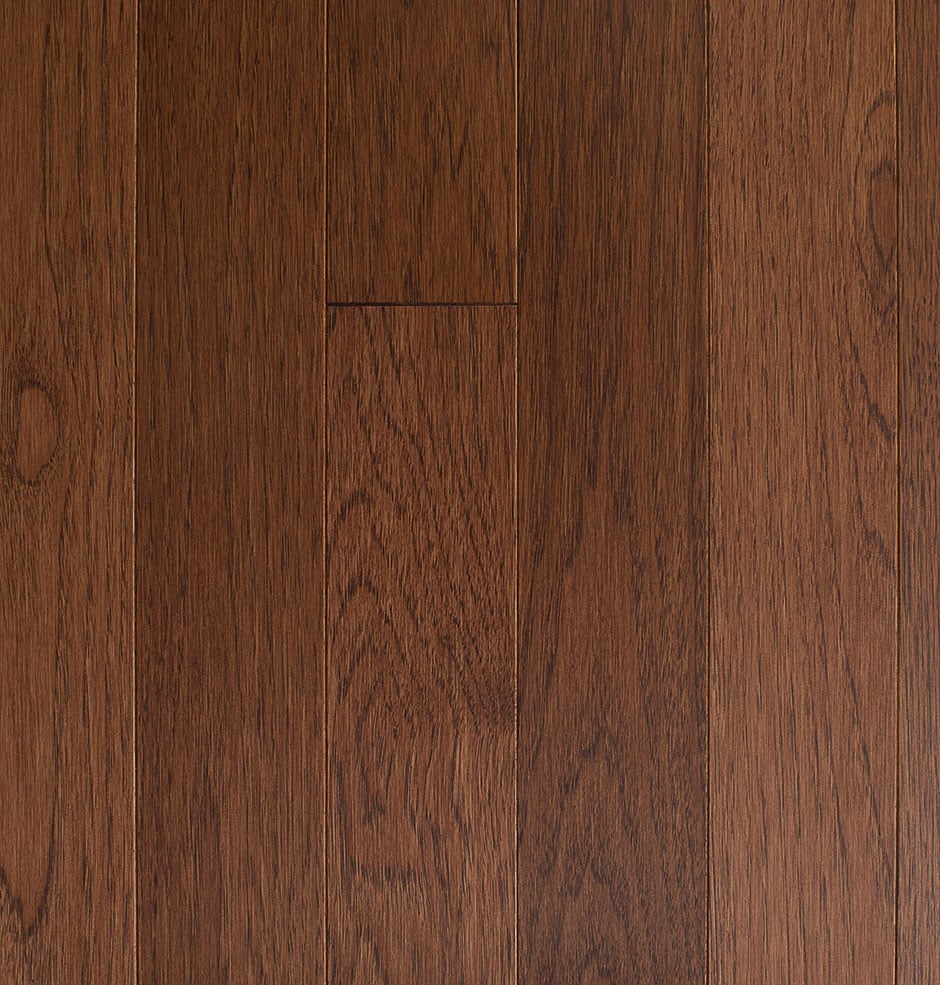

Urban Floor Collection

This line gives you options. Different tones, sizes, and styles let you match any design plan. Whether you’re a contractor fitting out a storefront or a DIYer refreshing your space, Urban Floor has the flexibility to fit right in.

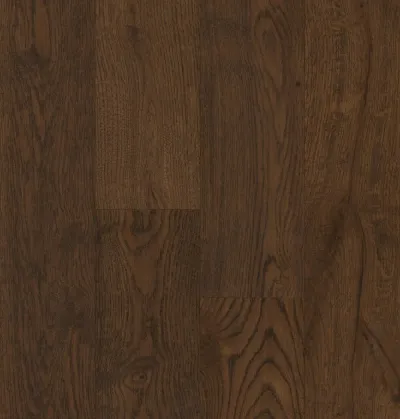

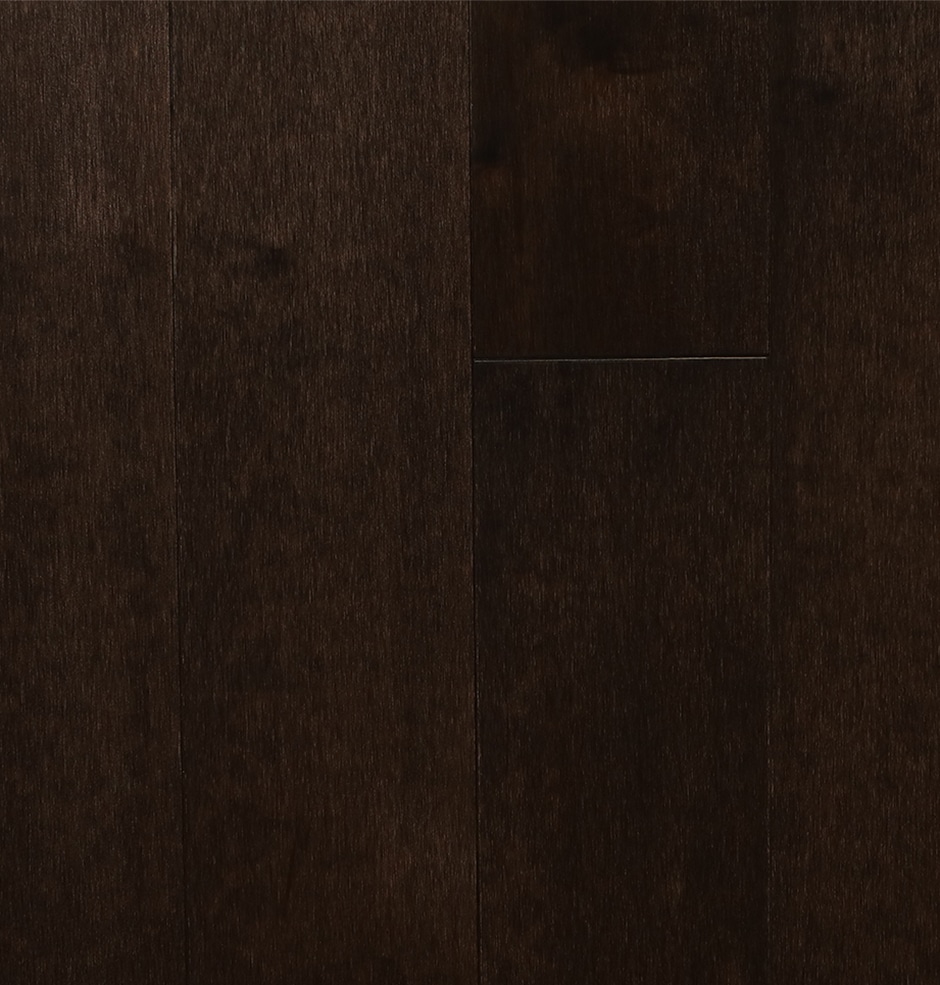

Naturale Elegance

We believe true beauty lies in the details. Our Naturale Elegance collection features finely crafted surfaces that highlight the raw charm of wood. It’s a refined choice for modern homes that value quality and quiet luxury.

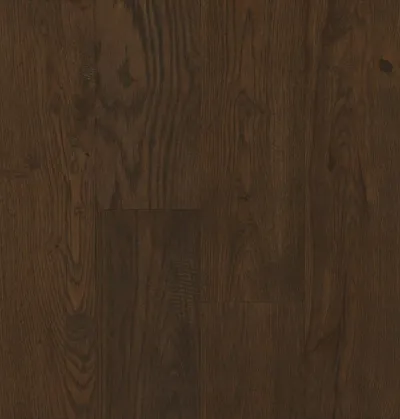

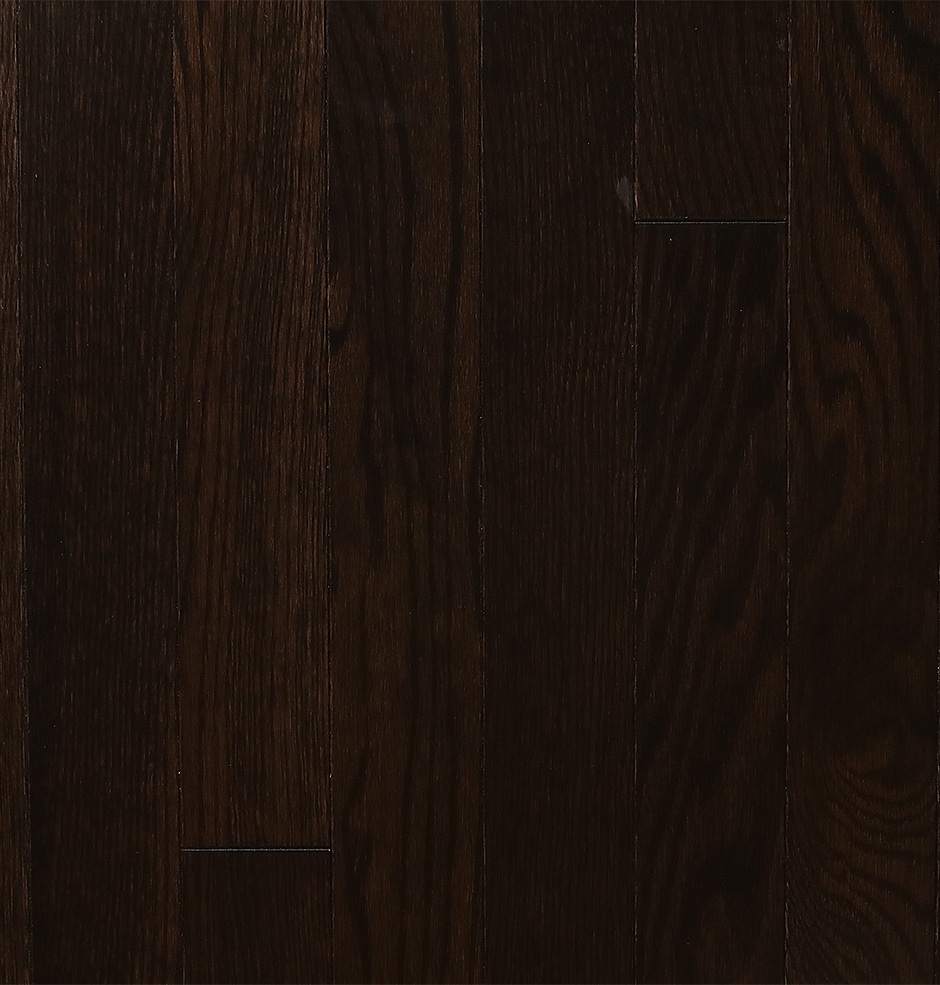

Wickham

At Wickham, we bring Canadian quality into every floorboard. Our engineered hardwood is crafted to withstand daily life while showcasing the unique beauty of real wood. We offer a wide range of colors and grains to fit your lifestyle.

Quick & Efficient Installation

The design of engineered hardwood facilitates a faster installation process, ensuring that your renovation project is completed with minimal disruption.

Brands We Trust, Quality You Can Stand On

At Rustic Wood Floor Supply, we work with brands that do it right. Our luxury engineered hardwood flooring collection is handpicked from mills known for consistent quality, strong performance, and standout design. We don’t just stock big names, but we choose partners like WD Flooring and Ten Oaks because their work speaks for itself.

These mills focus on proper milling, solid core construction, and finishes that last. Many of our options are proudly made in the USA, while others come from expert suppliers around the world. Every brand we carry is part of the National Wood Flooring Association, which means their wood is graded right and produced responsibly. Upgrade your space with confidence. Talk to our flooring experts today!

Structure & Installation of Engineered Hardwood

Rustic Wood Floor Supply provides engineered hardwood flooring with a strong multi-layer core of plywood or wood products arranged in different directions to prevent movement. On top, we add a thin veneer layer of real wood like oak or maple, which we stain and finish for beauty and durability. This layered design keeps our floors stable even in changing climates. When it comes to installation, we offer several trusted methods depending on your floor and subfloor type.

Our engineered hardwood flooring includes:

- Multi-layer core with 3, 5, or 7 layers for stability

- Thin 1mm–4mm veneer of real wood species

- Veneer glued and finished for protection

Our common installation suggested methods are:

- Floating: glue tongue and groove; DIY-friendly, not for all floors

- Nail Down: nails hold the floor; best for thicker boards

- Nail & Glue Assist: nails plus glue for strong, quiet floors

- Full Glue Down: adhesive on subfloor; best for concrete/slab

Chene

Villa Caprisi

L’Artiste

Roosevelt

Lena

Broadleaf

Hickory Engineered Hardwood

Maple Engineered Hardwood

Red Oak Engineered Hardwood

White Oak Engineered Hardwood

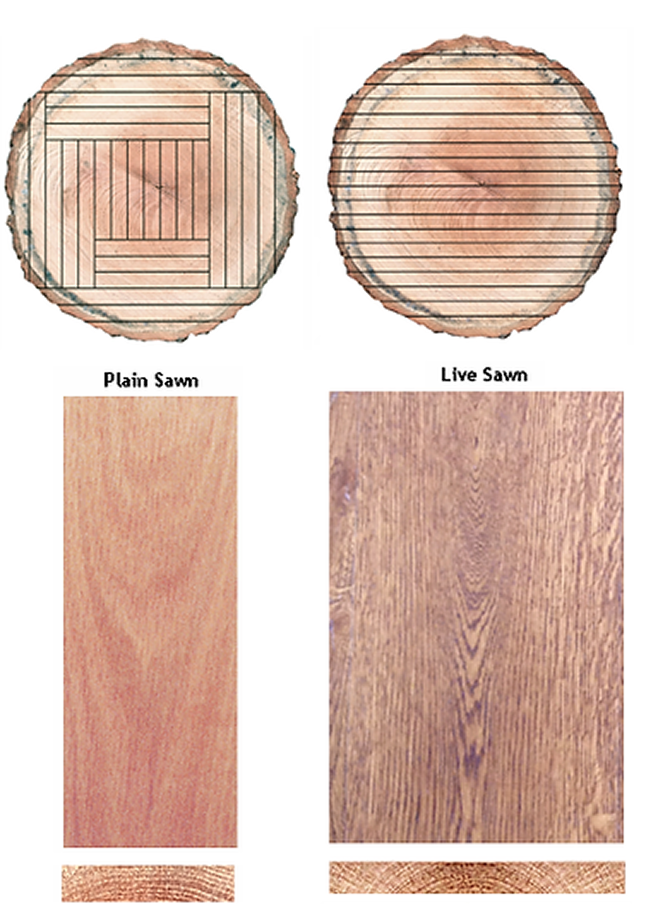

Our Hardwood Flooring Cuts

Plain Sawn Flooring

It is the standard cut at Rustic Wood Floor Supply that gets us 80%-85% of the log. You’ll see those cathedral arch patterns that most people recognize as classic hardwood. It’s cost-effective and gives you that traditional look.

Live Sawn Flooring

More contractors are asking for this lately. We cut straight through the log and use about 90% of it. The boards have cathedral patterns down the middle with straight grain on the sides. It gives you more variety in each plank.

Quarter Sawn Flooring

We quarter the log before cutting. This creates a flecked grain pattern that’s stable and doesn’t warp much. Only yields 50%-60% of the log, so it costs a bit more. No cathedral arches with this cut, but a unique character.

Rift Sawn Flooring

Cuts are made at 30°-60° angles from the edge of the log. Gives you straight, uniform grain with hardly any variation. We only get 30%-50% of the log, making it the most expensive & luxury option. Works well in modern designs.

Frequently Asked Questions

Yes, most engineered hardwood floors come pre-sealed with a factory-applied finish, making them ready to install without additional sealing.

Yes and no. Engineered hardwood is wood, so, it is as durable as solid hardwood. However, you are unlikely to be able to refinish it so you need to be sure to maintain the floor and buff & coat if possible every few years to ensure your investment lasts a long time.

Following are the top advantages:

- Colors – You will notice that engineered flooring has more color options than maybe you are used to. Not that site finish on solid hardwood flooring you can’t get these colors – it is usually hard and can be time-consuming. Most engineered flooring has multi-layered colors that are not easily reproducible with stains.

- No sanding – While sanding does take an extra day or 2 engineered flooring allows for anyone to install and be done after installation

- Cheaper price points – While cheaper isn’t always better, not everyone has money for solid hardwood. However, cheaper usually has more issues so be careful which cheap option you choose.

Coming from an industry professional, below are real disadvantages of engineered hardwood flooring that traditional flooring stores will not tell you or warn you about prior to buying flooring. Remember, we sell every flooring – we just make sure to fully educate our client’s customers to the fullest for the most informed decision before spending thousands to only find out the choice was wrong for them.

- Unable to refinish – most engineered flooring has small wear layers, hand scraping, or something else that does not allow for resanding. ONLY 4mm with no distressing can really be truly refinished 1-2 times.

- Delamination – these products use many layers of wood to create their product. You need to understand this is not one solid piece of wood and glue can and will fail.

- Different cuts expand and contract differently – Different manufacturers to get certain price points will use cheap wood that produces issues when it gets cold or heats up.

- More noise – You are putting many layers down that are thin. The nail that goes through these materials usually does not set correctly, why we recommend a glue assist. These nails will produce noise if not set correctly. Pops are within spec.

I mean, this one is impossible to truly answer. However, Ideally, even if you do not believe it solid hardwood is probably better overall. That does not mean that engineered flooring is not ideal for certain applications or homes. Solid hardwood is longer lasting since you are able to refinish it. Engineered is possibly better for you if you desire a very specific color, the flooring is going below grade and your timeline is very slim.

Engineered hardwood typically lasts between 20 and 30 years.

Because they do have a top layer of hardwood, like solid hardwood, they are susceptible to scratches.

If scratch resistance is important to you, look for engineered hardwood floors with a scratch-resistant top coat. Small scratches on engineered hardwood can be repaired a wax repair kit or a cotton cloth and some rubbing alcohol.

Since the popularity of engineered hardwood has grown, solid hardwood is generally on par with most higher end engineered floors. Cheaper floors like 3/8″ flooring will still be cheaper.

While engineered hardwood may look similar to laminate flooring, they are not the same.

Engineered hardwood contains a top layer of solid wood, while laminate flooring has a photographic layer coated with a wear-layer that appears to look like a wood surface.

In addition, laminate flooring is usually thinner than engineered hardwood.

This question really depends on a lot of factors. First and foremost, if you have major water damage the floor is ruined. Usually engineered floors are unable to be sanded since there is distressing, bevels and other things making sanding impossible. If you have no major damage a floor should last 20-30 years if maintained and you buff and coat the floor.

Engineered flooring is typically between 3/8” to 3/4” thick, whereas solid hardwood is 1/2” to 3/4“ thick.

When compared to other flooring options, engineered hardwood floors offer the following advantages:

- Affordability: Engineered hardwood flooring falls on the lower end of the wood flooring price scale, typically ranging from $4–$10 per square foot depending on thickness and species.

- Moisture-resistant: Although standard engineered hardwood isn’t waterproof, it does boast excellent water resistance, making it a better choice for moist environments such as kitchens and bathrooms.

- Easy to maintain: Engineered wood floors simply need regular sweeping or gentle vacuuming to maintain, and may occasionally be mopped with a wet mop and neutral cleaner to restore shine to their surface.

- Quick installation: The click-and-lock system offered by engineered wood flooring allows for a quick and easy installation.