Unfinished Hardwood Flooring

Tired of floors that wear out too quickly? Homeowners, contractors, and DIYers all face the same problem: low-quality flooring that needs constant repairs and replacements. Your home deserves better than a compromise.

We know how important it is to have durable, unfinished hardwood flooring that you can customize yourself. Rustic Wood Floor Supply offers premium wood you can finish your way, with options for wholesale buyers, too. Our American-sourced hardwoods stand the test of time in every room of your home.

Why settle for cheap unfinished hardwood flooring? Our floors hold up through years of everyday life, saving you time and money. From classic oak hardwood flooring to exotic walnut, we’ve got the perfect canvas for your vision. Professional installers trust us. DIYers recommend us. Families build memories on our floors.

Build it once. Love it forever.

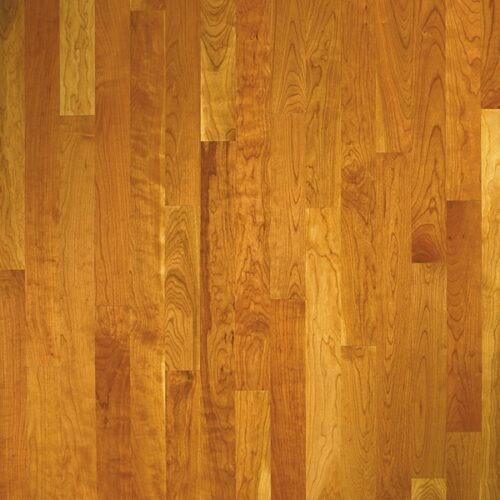

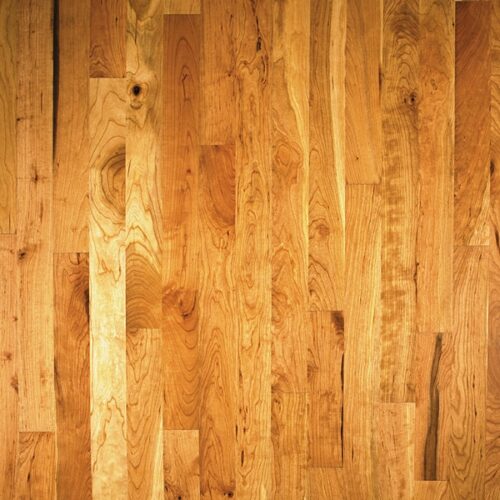

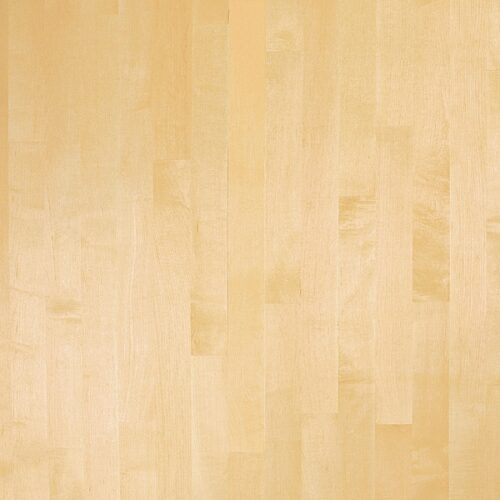

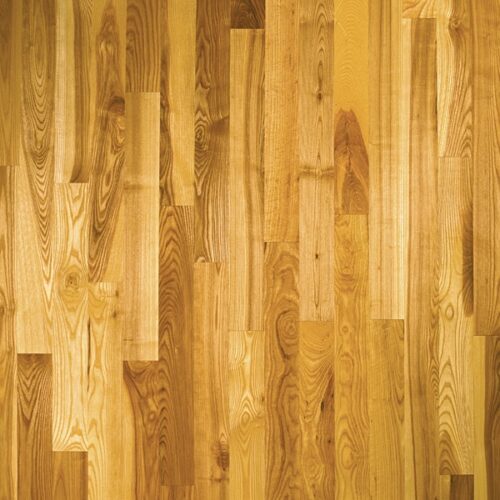

Species of Solid Unfinished Hardwood

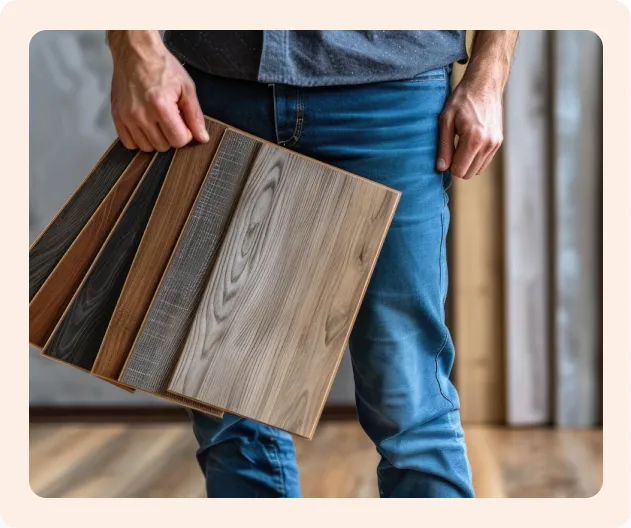

Our Solid Hardwood Cuts Fit Every Style

We partner with top American manufacturers like WD and Ten Oaks to bring you quality hardwood floors. These trusted companies create all our flooring right here in the USA using American trees and workers. Each cutting style offers a different look and feel, so you can find the perfect match for your home.

Why Experts Trust Our Solid Unfinished Hardwood?

When it comes to flooring that lasts for generations, we believe solid unfinished hardwood is the clear winner. Be a part of history by choosing solid unfinished hardwood flooring, created to last for generations and rooted in centuries of timeless tradition.

100% Natural

Our best unfinished hardwood flooring is made from 100% natural wood, designed to stay beautiful for decades. Proper care can make these floors endure for generations. This saves you money and helps us protect the environment by reducing waste.

Style of Your Choice

Our unfinished floors allow you to choose every detail of your stain, finish, and texture. When your tastes evolve, we make it easy to update your floors. Simply sanding and refinishing can create a fresh new look without replacing a single plank.

Wholesale Edge

We understand that ordering wholesale unfinished hardwood flooring can be tough. Unreliable stock and poor quality slow down your projects and cut into profits. At Rustic Wood Floor Supply, we solve these problems by offering premium unfinished hardwood flooring in bulk.

Made in the USA

All our hardwood comes straight from American mills. When you choose our flooring, you’re supporting local workers. You’re also investing in the quality and craftsmanship that only American-made materials can provide.

Frequently Asked Questions

Absolutely, unfinished hardwood flooring can be stained any color. Depending on the wood species will have an effect on the outcome color of what is being applied. You are also able to apply different textures to floors to make them look different.

Solid unfinished simply does not have a finish on it yet. Solid Prefinished flooring is unfinished flooring with a factory stain and finishes on it. Generally, these types of flooring are in the same category.

Well, you should hire a professional hardwood flooring installer/refinisher. Basically, you sand a floor with different machines, then put sealer on, and then the final finish coats on.

It won’t do anything but the wood will be unprotected. Some racquetball courts are unfinished but drinks and such are not allowed near them as it will cause issues. If you leave the wood unfinished it will ultimately become grey or black in color.

All floors are priced relative to the product quality. Cheaper wood like engineered 3/8″ vs 3/4″ flooring will be cheaper. generally, everything that Rustic Wood Floor Supply sells is priced the same across all sections of flooring based on quality. We have some prefinished items much more expensive than unfinished wood and some are more expensive. When you price the higher quality engineered woods against solid unfinished hardwood, unfinished is generally cheaper up front and in the long run.

Yes, solid hardwood flooring must be acclimated before installation. Wood naturally expands and contracts with changes in temperature and humidity, so acclimating the flooring helps prevent issues like warping or gaps.

In Atlanta’s climate, it’s recommended to let the wood sit in the installation area for at least 5-7 days (or as specified by the manufacturer). Keep the flooring in its original packaging and ensure the indoor environment is at normal living conditions—around 60-80°F and 30-50% humidity. Proper acclimation ensures a stable, long-lasting floor.

Yes, solid hardwood floors can develop cracks and experience movement due to natural expansion and contraction. Wood reacts to changes in temperature and humidity, which can cause minor gaps in drier conditions or slight swelling in higher humidity.

To minimize this, it’s important to properly acclimate the flooring before installation and maintain indoor humidity levels between 30-50%. Using a humidifier in dry seasons and a dehumidifier in humid months can help keep your floors stable and looking great for years to come.

Solid hardwood floors are one of the most durable flooring options and can last 50-100 years or more with proper care. Their longevity depends on factors like wood species, finish quality, maintenance, and environmental conditions.

One major advantage of solid hardwood is that it can be sanded and refinished multiple times, allowing homeowners to restore its beauty and extend its lifespan. Regular cleaning, maintaining proper humidity levels, and protecting the surface from excessive wear will help keep solid hardwood floors in excellent condition for generations.

Yes, solid hardwood flooring comes in a variety of colors, both naturally and through staining. Different wood species have unique tones—for example, Red Oak has warm reddish hues, White Oak is more neutral, and Walnut offers rich, dark brown tones.

If you want a custom color, unfinished solid hardwood can be stained to match almost any shade before applying a protective finish. This allows for endless possibilities, from light, modern tones to deep, classic hues, giving you complete control over your floor’s appearance.

Short Answer: Solid hardwood is 100% real wood, extremely durable, and can be refinished multiple times. Engineered wood has a hardwood top layer with a stable core, making it better for moisture-prone areas.

Expanded Comparison:

• Solid Hardwood is thicker (typically ¾”), lasts 50-100+ years, and can be refinished multiple times, making it a great long-term investment. However, it is more sensitive to moisture and humidity, so it’s best for above-grade installations like living rooms and bedrooms.

• Engineered Wood consists of a real wood top layer over a plywood or fiberboard core, offering greater stability in humid conditions. It’s ideal for basements, concrete slabs, and fluctuating climates, though refinishing is limited based on the wear layer thickness.

Which One to Choose? If you want a classic, long-lasting floor with refinishing flexibility, go with solid hardwood. If you need stability in moisture-prone areas, engineered wood is a great alternative.