Engineered Hardwood Spokane

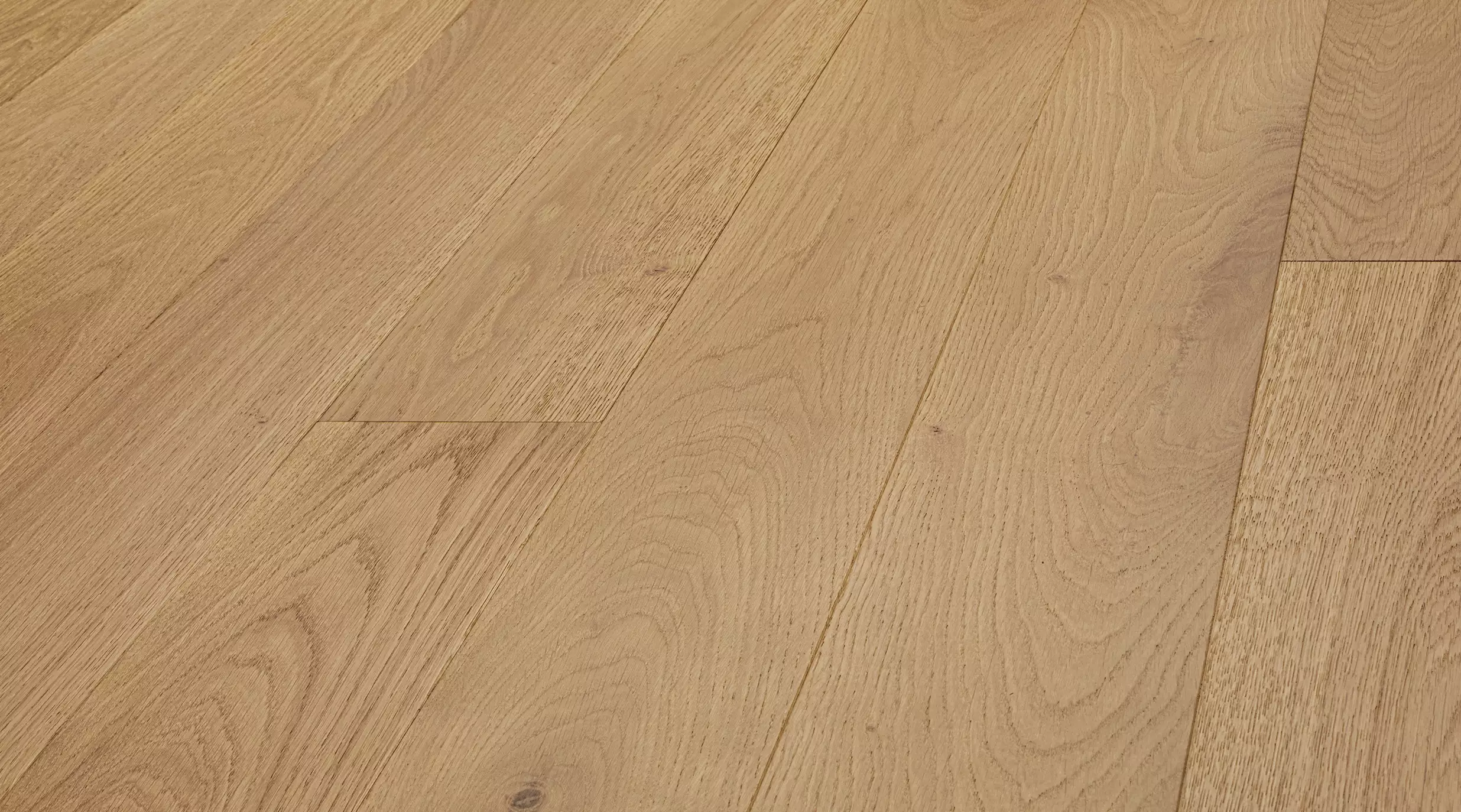

Spokane’s seasons are tough on traditional wood. Warping in winter. Gaps in summer. Homeowners need something stronger without losing the warmth of real hardwood. Rustic Wood Floor Supply’s engineered hardwood makes all the difference. Designed for stability, our engineered hardwood stands up to Spokane’s dry air and moisture swings. We’ve helped Spokane homes shine for years. Our engineered planks come factory-finished in rich, durable options.

Why fight your floor? Choose best engineered hardwood Spokane for comfort, strength, and style that fit your space from day one.

Find the Right Engineered Hardwood Type for Your Home in Spokane

Want to refresh your home with a flooring option that’s as beautiful as it is durable? Engineered hardwood offers the perfect blend of style and practicality. These floors bring both beauty and durability to your home with a range of exquisite collections that cater to every taste. Check out flooring store in Spokane top picks that promise to impress with their premium quality and exceptional designs.

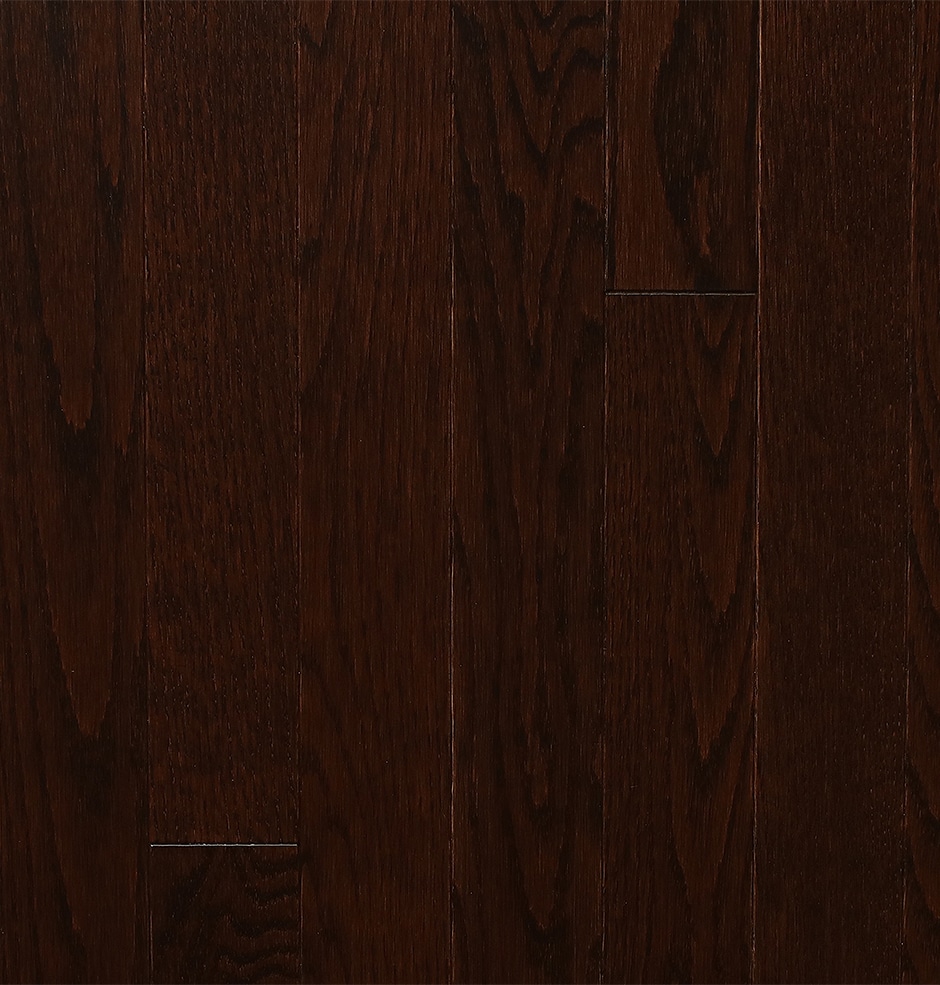

Cordalera Lakes Collection – Engineered Hardwood Spokane

Thickness: 5/8″ Veneer: 4mm Finish: UV finish

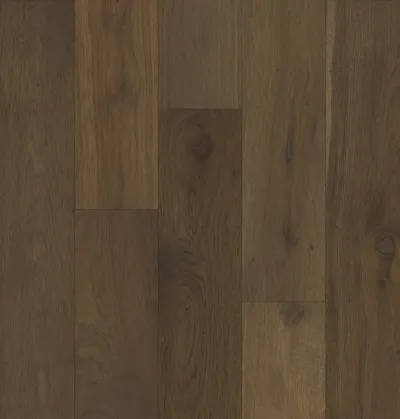

Urban Floor stands at the forefront of engineered hardwood with its premium selection. Featuring diverse colors, sizes, and finishes, Urban Floor ensures your floors reflect your unique style and elevate your home.

Chene

7.5″ and 1/2″ thickness with a 2mm wear layer.

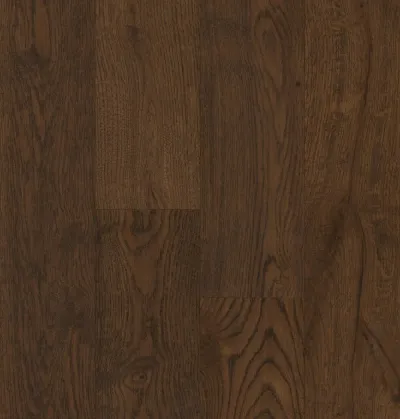

Villa Caprisi

9.5″ width with a 5/8″ thickness and a 4mm wear layer.

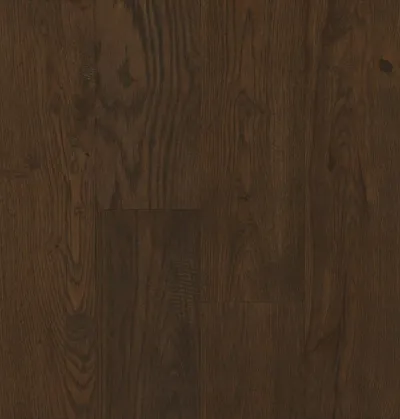

L’Artiste

8.625″ With with a 3/4″ thickness and a 6mm wear layer.

Roosevelt

Lena

Broadleaf

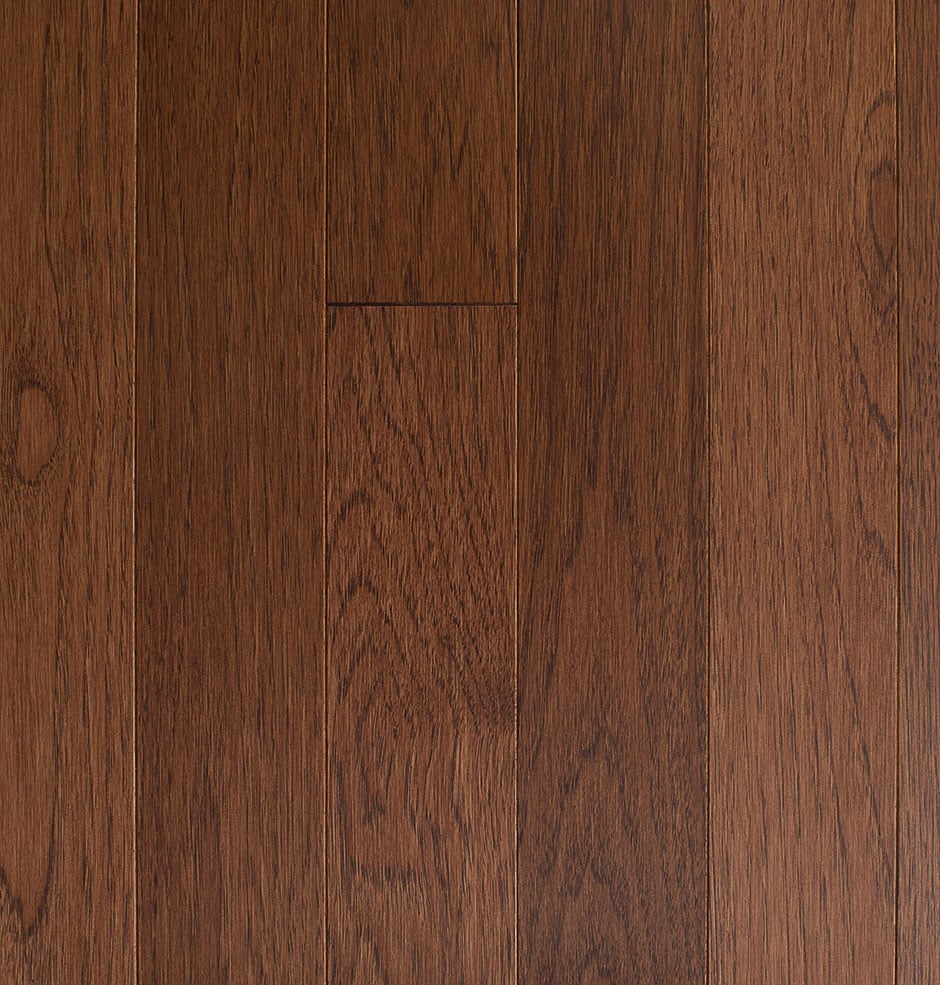

Hickory Engineered Hardwood Spokane

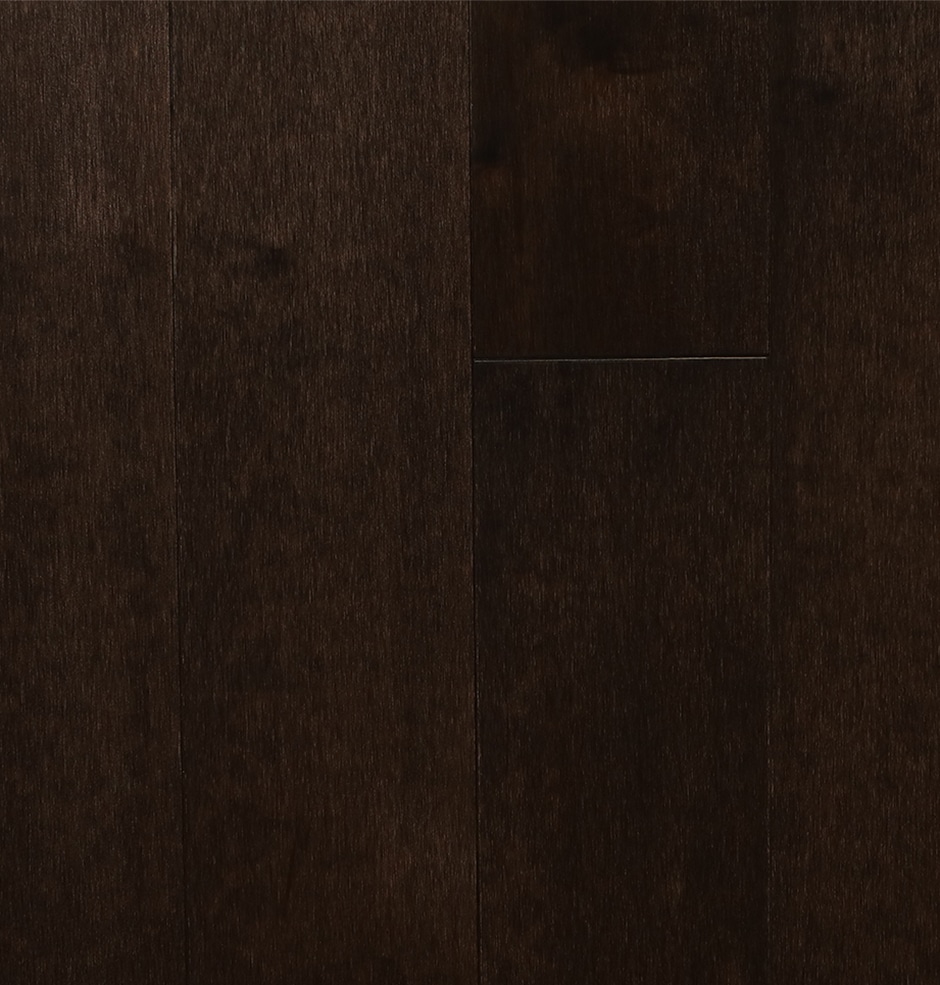

Maple Engineered Hardwood Spokane

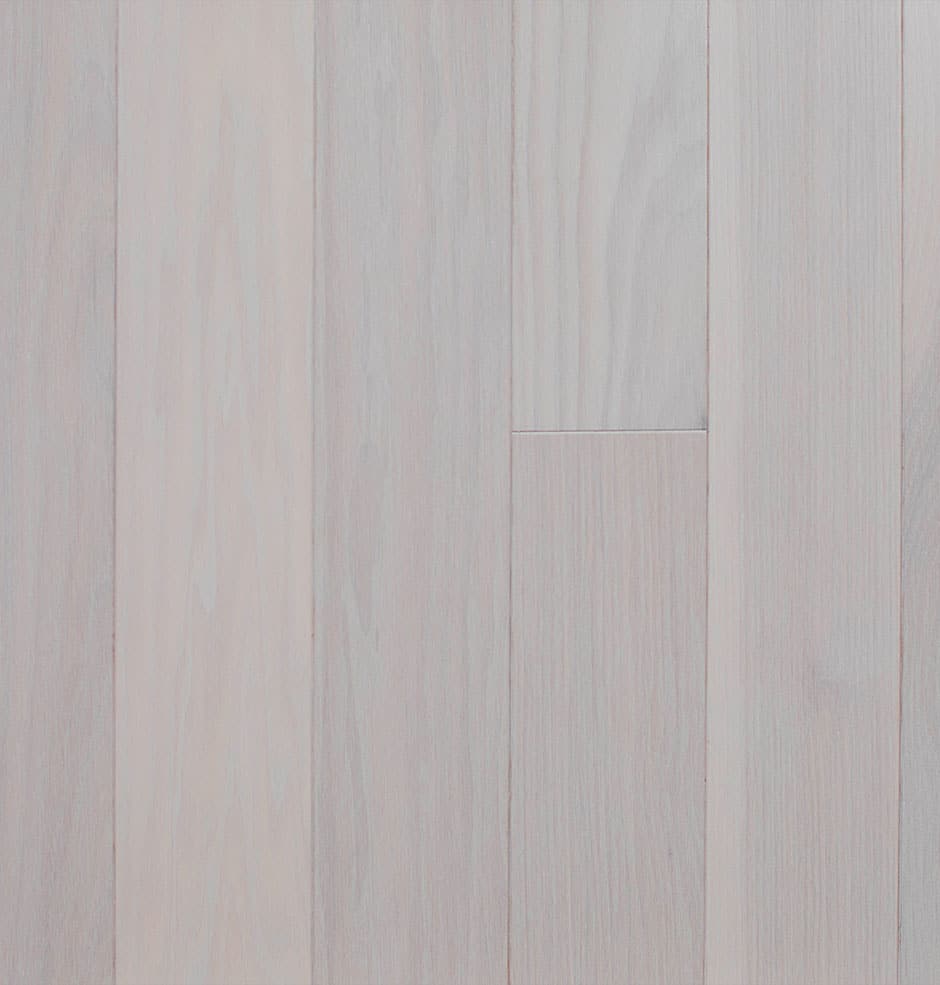

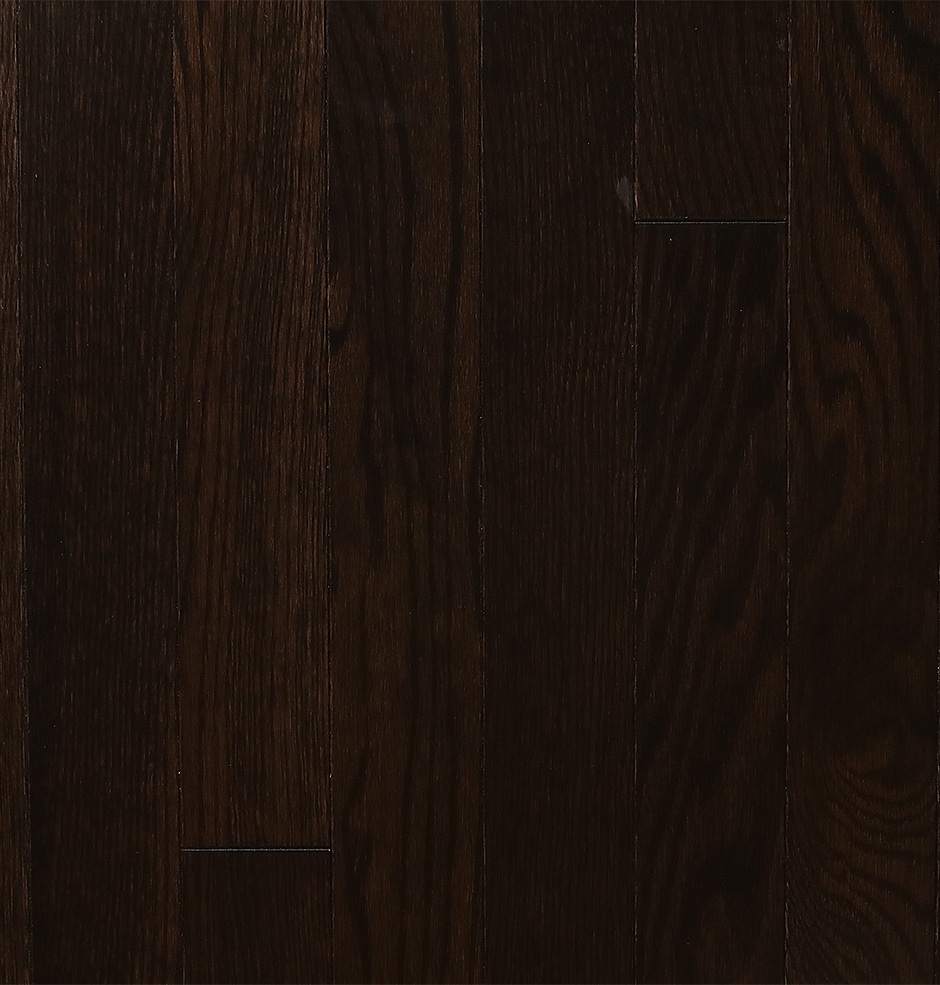

Red Oak Engineered Hardwood Spokane

White Oak Engineered Hardwood Spokane

Engineered Hardwood Spokane

Our engineered hardwood Spokane offers the perfect blend of beauty and durability, ideal for homeowners seeking a quick, hassle-free upgrade. Our Spokane hardwood range is perfect for high-traffic areas and is designed with multiple layers for added strength. Here’s why our engineered hardwood stands out:

Trusted by Leading Brands

When the most respected names in flooring trust us, you know you’re getting the best. Naturale Elegance, Urban Floor, and Wickham all choose our Spokane engineered wood and solid prefinished hardwood for its durability, timeless beauty, and low-maintenance qualities. These brands partner with us because they know our products deliver unmatched quality that stands the test of time.

Make your space shine with floors that lead the industry. Visit us now to get a discount on engineered hardwood flooring.

You’re About to Get the Best, We’ll Make Sure of It

At Rustic Wood Floor Supply, you’re not just getting a floor, but you’re getting a solution that’s built to last. Our collection of engineered hardwood Spokane is crafted with precision and designed to handle daily life, offering finishes that stay beautiful and strong for years to come. We don’t believe in shortcuts. Instead, we focus on delivering quality that enhances your space with the beauty, strength, and comfort you deserve.

See the difference quality makes. Schedule your consultation today!

TESTIMONIAL

Engineered Hardwood Flooring FAQ’s

Yes, most engineered hardwood floors come pre-sealed with a factory-applied finish, making them ready to install without additional sealing.

Yes and no. Engineered hardwood is wood, so, it is as durable as solid hardwood. However, you are unlikely to be able to refinish it so you need to be sure to maintain the floor and buff & coat if possible every few years to ensure your investment lasts a long time.

Following are the top advantages:

- Colors – You will notice that engineered flooring has more color options than maybe you are used to. Not that site finish on solid hardwood flooring you can’t get these colors – it is usually hard and can be time-consuming. Most engineered flooring has multi-layered colors that are not easily reproducible with stains.

- No sanding – While sanding does take an extra day or 2 engineered flooring allows for anyone to install and be done after installation

- Cheaper price points – While cheaper isn’t always better, not everyone has money for solid hardwood. However, cheaper usually has more issues so be careful which cheap option you choose.

Coming from an industry professional, below are real disadvantages of engineered hardwood flooring that traditional flooring stores will not tell you or warn you about prior to buying flooring. Remember, we sell every flooring – we just make sure to fully educate our client’s customers to the fullest for the most informed decision before spending thousands to only find out the choice was wrong for them.

- Unable to refinish – most engineered flooring has small wear layers, hand scraping, or something else that does not allow for resanding. ONLY 4mm with no distressing can really be truly refinished 1-2 times.

- Delamination – these products use many layers of wood to create their product. You need to understand this is not one solid piece of wood and glue can and will fail.

- Different cuts expand and contract differently – Different manufacturers to get certain price points will use cheap wood that produces issues when it gets cold or heats up.

- More noise – You are putting many layers down that are thin. The nail that goes through these materials usually does not set correctly, why we recommend a glue assist. These nails will produce noise if not set correctly. Pops are within spec.

I mean, this one is impossible to truly answer. However, Ideally, even if you do not believe it solid hardwood is probably better overall. That does not mean that engineered flooring is not ideal for certain applications or homes. Solid hardwood is longer lasting since you are able to refinish it. Engineered is possibly better for you if you desire a very specific color, the flooring is going below grade and your timeline is very slim.

Engineered hardwood typically lasts between 20 and 30 years.

Because they do have a top layer of hardwood, like solid hardwood, they are susceptible to scratches.

If scratch resistance is important to you, look for engineered hardwood floors with a scratch-resistant top coat. Small scratches on engineered hardwood can be repaired a wax repair kit or a cotton cloth and some rubbing alcohol.

Since the popularity of engineered hardwood has grown, solid hardwood is generally on par with most higher end engineered floors. Cheaper floors like 3/8″ flooring will still be cheaper.

While engineered hardwood may look similar to laminate flooring, they are not the same.

Engineered hardwood contains a top layer of solid wood, while laminate flooring has a photographic layer coated with a wear-layer that appears to look like a wood surface.

In addition, laminate flooring is usually thinner than engineered hardwood.

This question really depends on a lot of factors. First and foremost, if you have major water damage the floor is ruined. Usually engineered floors are unable to be sanded since there is distressing, bevels and other things making sanding impossible. If you have no major damage a floor should last 20-30 years if maintained and you buff and coat the floor.

Engineered flooring is typically between 3/8” to 3/4” thick, whereas solid hardwood is 1/2” to 3/4“ thick.

When compared to other flooring options, engineered hardwood floors offer the following advantages:

- Affordability: Engineered hardwood flooring falls on the lower end of the wood flooring price scale, typically ranging from $4–$10 per square foot depending on thickness and species.

- Moisture-resistant: Although standard engineered hardwood isn’t waterproof, it does boast excellent water resistance, making it a better choice for moist environments such as kitchens and bathrooms.

- Easy to maintain: Engineered wood floors simply need regular sweeping or gentle vacuuming to maintain, and may occasionally be mopped with a wet mop and neutral cleaner to restore shine to their surface.

- Quick installation: The click-and-lock system offered by engineered wood flooring allows for a quick and easy installation.